Technology Overview

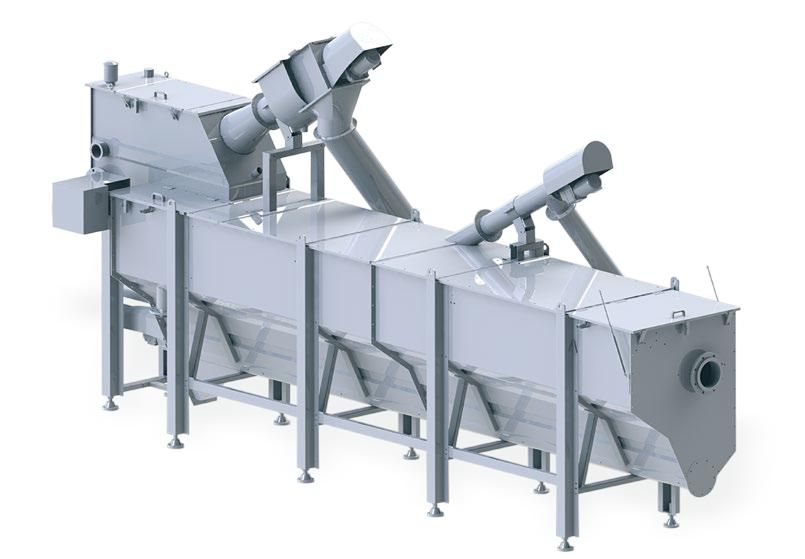

Untreated sewage first passes through a screw screen, which effectively removes larger floating and suspended materials, known as screenings. The screened sewage then flows into a longitudinal sedimentation tank where sand and other heavy particles, referred to as grit, settle out and are removed by a system of screws.

A horizontal shaftless grit conveying screw transports settled grit to the sump. Grit is then removed from the sump via a shafted extraction screw which lifts the grit from the tank for discharge into a bin. Additionally, the system can be configured to remove fats, oils, and grease (FOG), offering enhanced treatment where required.

Key Features

- Small footprint & minimal civil works

- Ease of installation and operation

- Low operating costs and maintenance

- Low organic matter in the solid residue extracted

- Reduction up to 40% in volume of solids removed

- No odours

Technical Specifications

Standard Specifications

*1Theoretical, calculated using clean water; reference design basis: influent TSS 500 mg/L with up to 0.5% grit; typical performance: up to 90% removal efficiency for grit particles >200 μm and density > 1,650 kg/m3, *2Flanges are lap joint max 15mm thick with holes P16 according to AS4087, *3Refer to MAK Water product data sheet SSB-mK for more details, *4 Refer to schematic, *5 Based on machine configuration, motor power could be different

Standard Inclusions and Options

*1Standard air blower system includes: motor TEFC premium efficiency IP55 with thermistor, 1” fittings with SS hoses, retention valve, pressure valve, pressure switch, suction filter, wiring & full installation, outdoors side installation, no additional protective covering, *2 Lap joint flange with holes PN16 according to AS4087 *3Stainless steel parts: stripping with acid solution, passivation with glass particles, final surfaces cleaning with anti-dust oil. Carbon steel parts: sandblasting SA 2.5 for external anti-rust paint RAL 5015

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Screening