Technology Overview

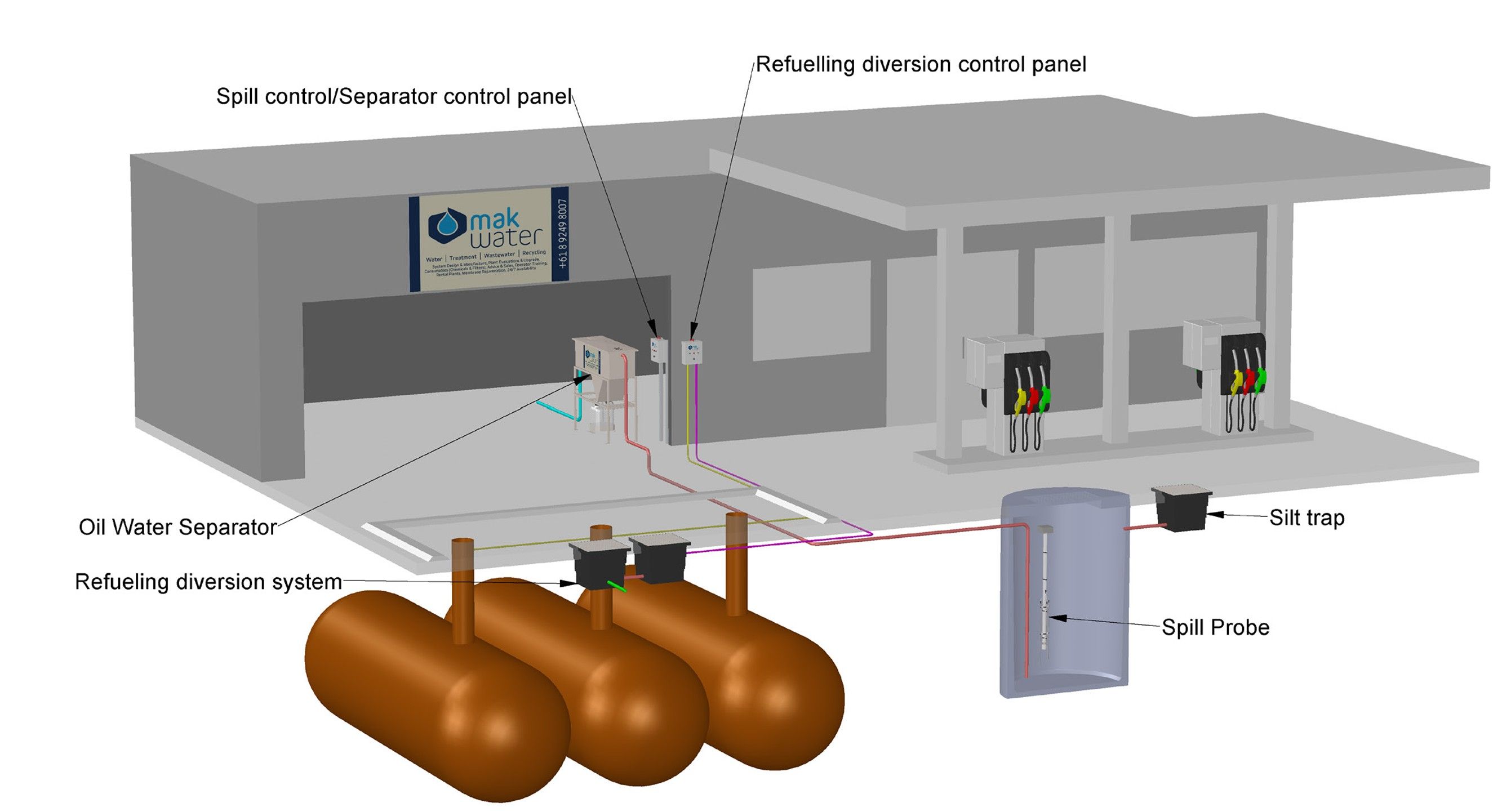

The spill control system operates largely in the same manner as a standard oil water separator system. Wastewater is captured from the hardstand area in a holding tank for pre-treatment.

The key function and difference of this system is the use of a conductive spill/pump-run probe assembly to govern the operation of the pump and detection of gross spills. This probe is capable of sensing conductivity through water, but not through oil/hydrocarbons thus enabling the probe to determine what the influent liquid is, and whether it is safe to pump through the separator unit.

As the tank fills, the conductive spill probe assembly measures the conductivity of the influent liquid first between the low-level and reference probes, followed by the high-level and reference probes. The pump does not start until conductivity has been sensed between both the low/reference probes and the high/reference probes.

In the event of a gross spill, or a cumulative build up, typically greater than 150L, the Spill/Alarm Level Micro Float will lift prior to conductivity being sensed between the high-level and reference probes. This indicates a spill to the controller and will lock the system out from operation until the holding tank has been emptied by a waste removal contractor reset - ting the system.

Technical Specifications

Standard Inclusions and Options

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Storm Water