Technical Specifications

Standard Specifications

- Based on influent wastewater TSS not exceeding 400 mg/L, maximum capacity, not to be exceeded 2. Optional in-tank version (screen installed in tank) 3. Flanges are stainless steel lap joint type, 15mm thick, according to AS4087 PN16 4. Can be operated without washing for influent wastewater TSS < 250 mg/L

Standard Inclusions and Options

✓ = Standard Supplyo = - = Not Applicable

- Stainless steel parts: stripping with acid solution, passivation with glass particles, final surfaces cleaning with anti-dust oil. Carbon steel parts: sandblasting SA 2.5 for external anti-rust paint RAL 5015

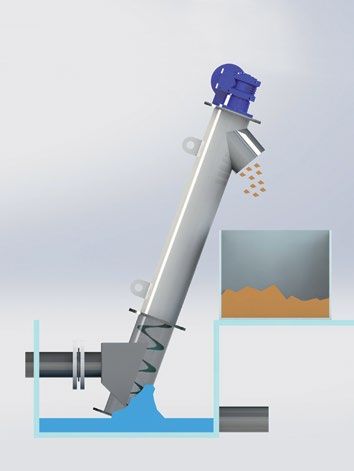

Screening & Grit Handling