Brackish Water Reverse Osmosis – Basic

MAK Water’s Brackish Water Reverse Osmosis – Basic (BWROB) plants are pre-engineered products, designed to suit simple applications where a high level of electrical instrumentation and controls is not required, and the feed water quality falls within the parameters defined in the data sheet.

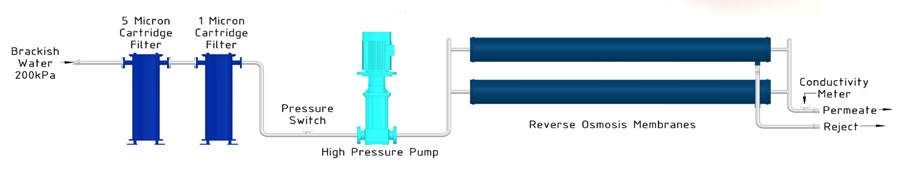

The standard treatment process involves pre-filtration (5 and 1 micron cartridge filters) and RO desalination. The BWROB is designed to operate continuously until the permeate tank is filled, or feed water is unavailable.

The BWROB is available with a pre-determined number of standard options and is supplied with a generic documentation package.

Technical Specifications

Standard Specifications

Parameter | Units | BWROB-010 | BWROB-015 | BWROB-025 | BWROB-030 | BWROB-035 | BWROB-050 |

|---|---|---|---|---|---|---|---|

| Permeate flow rate | m3/day | 10 | 15 | 25 | 30 | 35 | 50 |

| Permeate recovery rate | % | 40~70 (varies according to feed water quality and RO configuration) | |||||

| Ambient design temperature | °C | 1~35 (1~43 with optional air conditioned container) | |||||

| Feed water inlet pressure | kPa | min. 200~500 max. (flooded suction only with optional low pressure feed pump) | |||||

| Permeate discharge pressure | kPa | ~40 | |||||

| Brine discharge pressure | kPa | ~40 | |||||

| Power supply | - | AC 240V, 1 Phase, 50Hz | |||||

| Power consumption (approx.) | kW | 2 | 2 | 2 | 3 | 3 | 5 |

| Control panel IP rating | - | IP50 | |||||

| Skid dimensions (approx.) | mm | 1,500W x 1,700H x 680D | |||||

| Skid weight (approx.) | kg | 150 | 160 | 170 | 180 | 190 | 200 |

| Container size (optional) | - | 10’ ISO | |||||

| UV disinfection (optional) | UV dose | >40 mJ/cm2 @ 90% UVT | |||||

| Distribution pump set (optional) | m3/hr @ 300kPa | 1.04 | 1.56 | 2.6 | 3.13 | 3.65 | 5.21 |

Parameter | Units | Feed water | Permeate |

|---|---|---|---|

| Total dissolved solids (TDS) | mg/L | <3,000 | <500 (typical) |

| Temperature | ˚C | 15~30 | - |

| pH | pH units | 5~8.5 | - |

| Total suspended solids (TSS) | mg/L | <5 | <1 |

| Particle size | µm | >1 | - |

| Silt density index | - | <5*1 | - |

| Free chlorine | mg/L | 0 (<2 with optional GAC filter) | 0 (0.2~2.0 with optional chlorine disinfection) |

| Dissolved iron | mg/L | <0.1 | - |

| Dissolved manganese | mg/L | <0.1 | - |

| Biological oxygen demand (BOD) as O2 | mg/L | <10 | - |

| Chemical oxygen demand (COD) as O2 | mg/L | <10 | - |

| Total organic carbon (TOC) | mg/L | <3 | - |

*1Increased membrane fouling will occur where feed water SDI exceeds 3

Standard Inclusions and Options

Equipment | BWROB-010 | BWROB-015 | BWROB-025 | BWROB-030 | BWROB-035 | BWROB-050 | |

|---|---|---|---|---|---|---|---|

| Skid mounted plant | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| uPVC pipe work with isolation, non-return and sampling valves | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Inlet pressure regulating valve*1 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Solenoid valves (inlet feed and CIP/flush) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Low pressure feed pump | o | o | o | o | o | o | |

| High pressure RO pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| RO pressure vessels and membranes with reject control valve | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Concentrate recirculation with throttling valve | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Hose connections for membrane clean in place (CIP)*2 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Control panel with indicator lamps, isolators and e-stop | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Pre-RO treatment | Cartridge filters (5 and 1 µm) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Auto-backwashing GAC filter*3 | o | o | o | o | o | o | |

| Anti-scalant dosing*4 | o | o | o | o | o | o | |

| Post-RO treatment | Flow paced chlorine dosing | o | o | o | o | o | o |

| UV reactor with ballast*5, 6 | o | o | o | o | o | o | |

| Containerised system with overhead lighting and air conditioning | o | o | o | o | o | o | |

| Permeate distribution pump with controller*5 | o | o | o | o | o | o | |

*1Not supplied where low-pressure feed pump option is taken, *2CIP tank and pump by others, *3For free chlorine removal, *4May be required depending on feed water quality, consult MAK Water, *5Separate power connection required, *6UV system supplied loose for installation by others

Instrumentation | Included | |

|---|---|---|

| Level switches | Feed water tank | ✓ |

| Permeate tank | ✓ | |

| Anti-scalant dosing tank (optional) | ✓ | |

| Chlorine dosing tank (optional) | ✓ | |

| Pressure switches | Low pressure feed pump discharge (optional) | ✓ |

| High pressure RO pump discharge | ✓ | |

| Permeate distribution pump (optional) | ✓ | |

| Pressure gauges | Feed water inlet or low pressure pump discharge (optional) | ✓ |

| GAC filter discharge (optional) | ✓ | |

| Cartridge filter discharge | ✓ | |

| High pressure RO pump discharge | ✓ | |

| Brine discharge | ✓ | |

| Flow indicators (rotameters) | Permeate | ✓ |

| Reject | ✓ | |

| Recirculation | ✓ | |

| Conductivity meter | Permeate | ✓ |

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

A Western Australian glass and stone manufacture was continually having issues with water marks being left on their glass sheets after they have been washed down. The company contacted MAK Water to design, construct and commission a water treatment process that treated their mains water supply to a standard that eliminated the smear marks after washing the glass sheets.

Western Australia

A major defence contractor reached out to MAK Water to discuss options for demineralised water treatment. The client required low conductivity water for to top up battery water on naval vessels. Demineralised water was needed at two different locations and the client had a tight schedule to ensure continuity of service. Following a full consultative review MAK Water designed a containerised Brackish Water Reverse Osmosis – Basic (BWRO-B-010) plant that uses a MAKPAK ion exchange process to treat scheme water to below 5µs/cm conductivity. The plant was delivered on-time, in-budget and producing water well below the conductivity in the design specification. This enabled the client to top up batteries with low conductivity water reducing the risk of the batteries losing capacity and extending battery life. As a result of the success of this project MAK Water has been asked to consult with international allies to produce a similar solution for their own use.

Western Australia

What people are saying

We worked with MAK Water on the installation of a Reverse Osmosis (RO) plant, it was designed, built, installed on time and to budget. It perfectly meets the needs of our simulated workplace environment, providing a practical, high-quality learning resource.

A/Director - Science, Resources and Environment

North Metropolitan TAFE, Perth

Reverse Osmosis Desalination

Related Solutions

Brackish Water Reverse Osmosis

MAK Water’s Brackish Water Reverse Osmosis (BWRO) desalination plants are designed to treat ground/surface or industrial water with <5,000 mg/L of dissolved solids (TDS) and <30 mg/L of suspended solids (TSS), to achieve potable water quality.

Demineralised Water Reverse Osmosis

MAK Water’s Demineralised Water Reverse Osmosis (DMRO) Plants are designed to treat fresh water, with < 1,000 mg/L of dissolved solids (TDS) and < 30 mg/L of suspended solids (TSS), to produce high purity demineralised water with TDS < 1 mg/L.

Sea Water Reverse Osmosis

MAK Water’s Sea Water Reverse Osmosis (SWRO) plants are designed to treat sea water, or high salinity ground water, with < 40,000 mg/L of dissolved solids (TDS) and < 30 mg/L of suspended solids (TSS), to achieve potable water quality.