Sea Water Reverse Osmosis

MAK Water’s Sea Water Reverse Osmosis (SWRO) plants are designed to treat sea water, or high salinity ground water, with < 40,000 mg/L of dissolved solids (TDS) and < 30 mg/L of suspended solids (TSS), to achieve potable water quality.

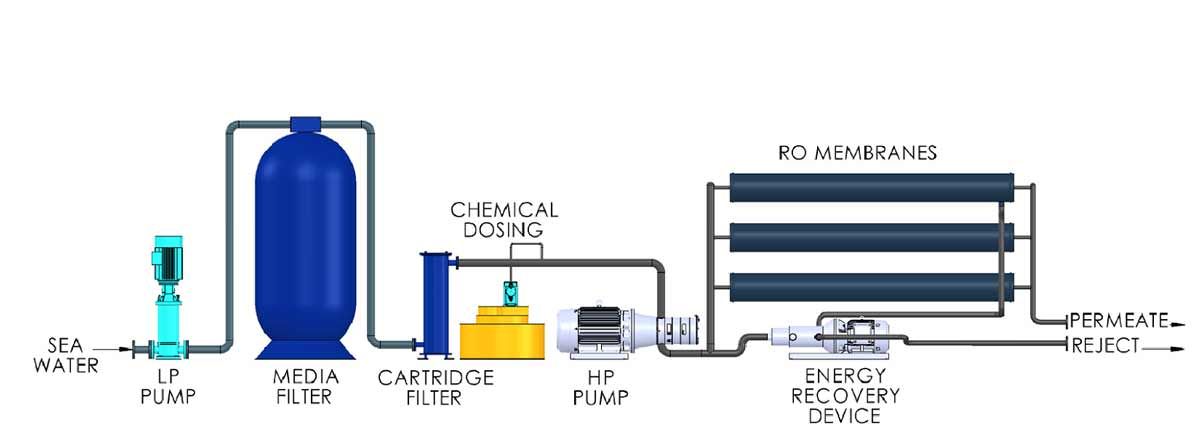

The standard treatment process involves pre filtration (auto-backwashing multimedia filters and cartridge filters), anti-scalant dosing to prevent membrane scaling, RO desalination and auto flushing and CIP systems for membrane cleaning. Additional pre-RO and post-RO treatment steps may be added as required to suit feed water conditions and/or treated water quality requirements.

All MAK Water SWRO plants are available as skid mounted or containerised systems.

Tech specs

Standard Specifications

Parameter | Units | SWRO-50 | SWRO-100 | SWRO-150 | SWRO-250 | SWRO-500 | SWRO-1000 | |

|---|---|---|---|---|---|---|---|---|

| Permeate Flow Rate | m3/day | 50 | 100 | 150 | 250 | 500 | 1000 | |

| Permeate Recovery Rate | % | 40 (typical) | ||||||

| Permeate TDS | mg/L | <500 (typical) | ||||||

| Raw Water TDS | mg/L | <40,000 | ||||||

| Raw Water TSS | mg/L | <30 | ||||||

| Raw Water Temperature | °C | 15 ~ 35 | ||||||

| Ambient Design Temperature | °C | 5 ~ 45 (-15 ~ 50 for insulated containerised system) | ||||||

| Feed Water Inlet Pressure | kPa | >15 (flooded suction) | ||||||

| Permeate Discharge Pressure | kPa | ~40 (higher discharge pressures available on request) | ||||||

| Brine Discharge Pressure | kPa | ~40 (higher discharge pressures available on request) | ||||||

| Power Supply | - | AC 380~450 V, 3Phase, 50/60 Hz | ||||||

| PowerConsumption | Standard | kW | 20 | 25 | 35.5 | 52.5 | 105 | 190 |

| High Efficiency | - | - | 26 | 43 | 71 | 142 | ||

| No. Containers (Optional) | - | 1 x 20' | 1 x 20' | 1 x 40' | 1 x 40' | 2 x 40' | 2 x 40' | |

Tech specs

Standard Inclusions + Options

Equipment | SWRO-50 | SWRO-100 | SWRO-150 | SWRO-250 | SWRO-500 | SWRO-1000 | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Skid Mounted Plant & Equipment | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| Low Pressure Feed Pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| High Pressure RO Pump (c/w ERD) | Std Efficiency | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||

| High Efficiency | - | - | o | o | o | o | |||||||||||||||

| Pre-filtration | Multimedia | o | ✓ | ✓ | ✓ | o | o | ||||||||||||||

| Ultra Filtration | o | o | o | o | ✓ | ✓ | |||||||||||||||

| Cartridge Filters | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| Anti Scalant Dosing System | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| Membrane CIP & Auto Flush System | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| PLC Control System with HMI | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| Containerised system, c/w A/C & Lights | o | o | o | o | o | o | |||||||||||||||

| Container Insulation (walls & ceiling) | o | o | o | o | o | o | |||||||||||||||

| Container non-slip floor coverings | o | o | o | o | o | o | |||||||||||||||

| Container Side Access Door | o | o | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| Additional Pre-RO Treatment | o | o | o | o | o | o | |||||||||||||||

| Additional Post-RO Treatment | o | o | o | o | o | o | |||||||||||||||

| Premium Instrumentation Package | o | o | o | o | ✓ | ✓ | |||||||||||||||

| Permeate Distribution Pump Set | o | o | o | o | o | o | |||||||||||||||

Instrumentation | Standard Package | Premium Package | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Gauges | ✓ | ✓ | |||||||||||||||||||

| Pressure Transmitters (4-20 mA) | - | ✓ | |||||||||||||||||||

| HP RO Pump Inlet Low Pressure Switch | ✓ | ✓ | |||||||||||||||||||

| Flow Gauges (Rotameters) | ✓ | - | |||||||||||||||||||

| Flow Transmitters (4-20 mA) | - | ✓ | |||||||||||||||||||

| Conductivity Transmitter (4-20 mA) | ✓ | ✓ | |||||||||||||||||||

| Float Switches (Feed/Permeate, Chemical Dosing & CIP Tanks) | ✓ | ✓ | |||||||||||||||||||

| Remote Monitoring & Control Capabilities | - | ✓ | |||||||||||||||||||

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Yara is the world’s largest producer of ammonia, nitrates and NPK (nitrogen, phosphorus and potassium) fertilisers and owns and operates the Technical Ammonium Nitrate (TAN) facility, adjacent to an existing liquid ammonia plant on the Burrup Peninsula. During commissioning of the TAN plant, Yara needed additional demineralised water for boiler feed water and hired a plant from MAK Water for short term, high quality water supply. MAK has a large hire fleet of reverse osmosis (RO) plants and was able to customise available plants to meet the urgent requirement. This was not a normal RO application as the feed was seawater and demineralised water was required.

Karratha, Western Australia

The first stage of the Wheatstone LNG Project commenced with a temporary fly camp for construction workers. MAK Water was engaged to supply modular Potable Water and Wastewater treatment plants with additional capacity able to handle the initial 500 man fly camp and the start of the main construction camp. MAK Water took responsibility for the turnkey supply and installation of a Sea Water Reverse Osmosis (SWRO) and membrane bioreactor (MBR) to treat the sewage to a standard suitable for reuse in industrial applications.

Onslow, Western Australia

In late 2012, the Australian Federal Government established a refugee processing centre on the remote pacific island of Nauru. The situation was critical, requiring swift delivery of humanitarian assistance. There was insufficient drinking water available, so a fresh drinking water supply was urgently required for the additional population.

Pacific Islands, Nauru

As part of its Pluto project, Woodside needed to upgrade the port and associated infrastructure at the Burrup Materials Facility in the Pilbara region of Western Australia. Water supply to the port facilities was insufficient for the construction contractor to complete civil and concrete works and therefore an alternative water supply was required. The project was only forecast to last 12 months, and following completion the water demand would reduce substantially. Consequently a temporary solution was required.

Pilbara, Western Australia

Potable Water for Remote Community

The Government of Western Australia (WA) Housing Authority manages essential services at Aboriginal communities in the remote outback of WA via the Remote Area Essential Services Program (RAESP). Local Regional Service Providers are engaged by Housing Authority for the delivery of essential services to these communities. MAK Water has now supplied eight of these communities with potable water treatment plants to improve the drinking water quality and reduce the impact of water born viruses in the community. This project required a custom designed Sea Water Reverse Osmosis (SWRO) plant to produce potable water using the available hypersaline ground water.

Eastern Goldfields, Western Australia

Reverse Osmosis Desalination

Related Solutions

Brackish Water Reverse Osmosis

MAK Water’s Brackish Water Reverse Osmosis (BWRO) desalination plants are designed to treat ground/surface or industrial water with <5,000 mg/L of dissolved solids (TDS) and <30 mg/L of suspended solids (TSS), to achieve potable water quality.

Brackish Water Reverse Osmosis – Basic

MAK Water’s Brackish Water Reverse Osmosis – Basic (BWROB) plants are pre-engineered products, designed to suit simple applications where a high level of electrical instrumentation and controls is not required

Demineralised Water Reverse Osmosis

MAK Water’s Demineralised Water Reverse Osmosis (DMRO) Plants are designed to treat fresh water, with < 1,000 mg/L of dissolved solids (TDS) and < 30 mg/L of suspended solids (TSS), to produce high purity demineralised water with TDS < 1 mg/L.