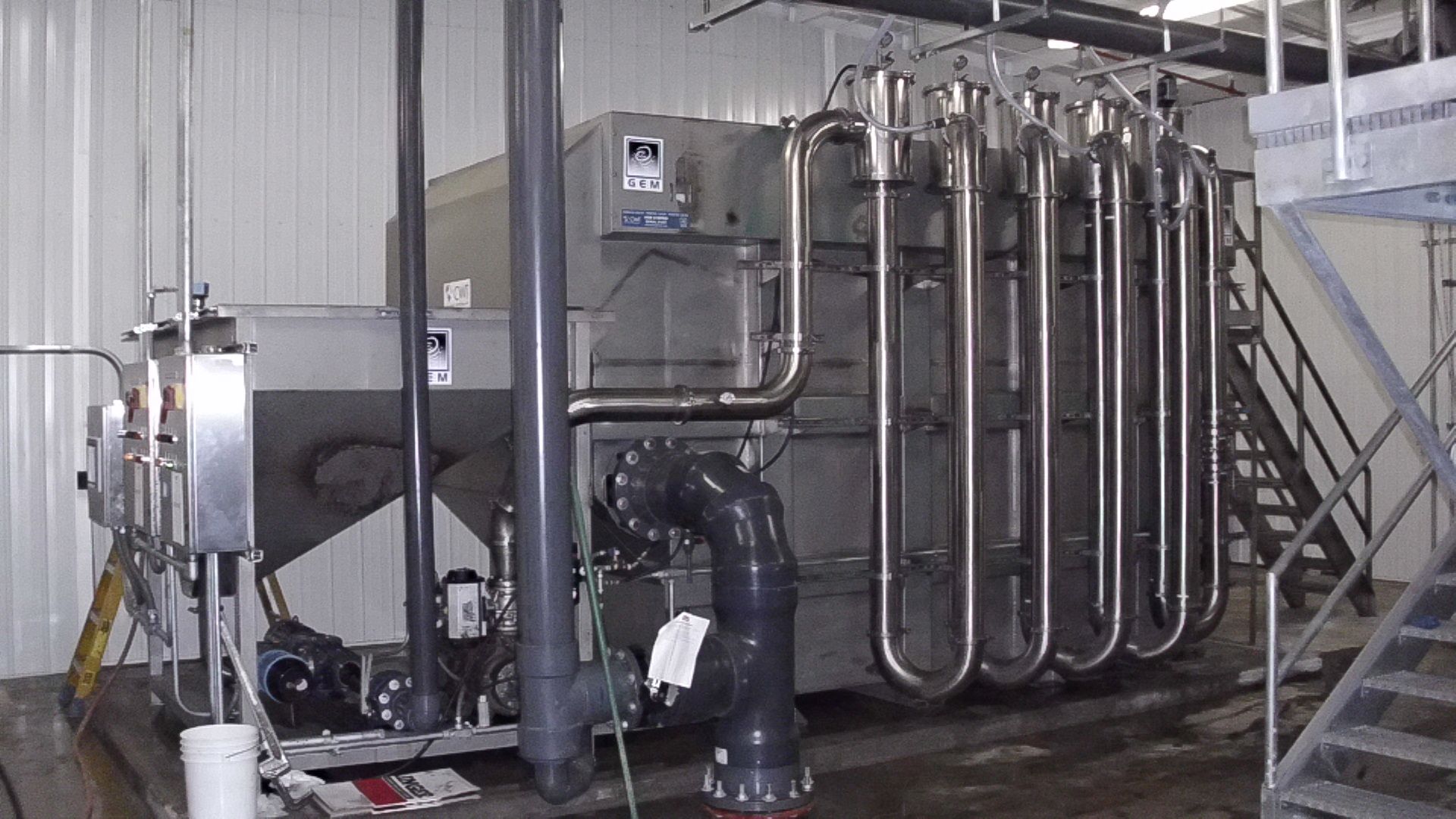

GEM® System Overview

The GEM System ensures unrivalled removal efficacy for Total Suspended Solids (TSS), Fats, Oils, Grease (FOG), and the Suspended Components of Biological Oxygen Demand and Chemical Oxygen Demand (BOD/COD).

This patented LSGM (Liquid Solid Gas Mixing) technology utilises specialised cartridges to generate energy and achieve complete air mixing throughout the entire waste stream. By efficiently separating solids from liquids, it effectively prevents their entry into the skimmer tank, ensuring optimal performance. The LSGM’s use hydrocyclone / centrifugal energy to provide extremely high energy mixing of wastewater, oxygen and polymers. 100% aeration/oxygenation generates 1,000 times more NANO bubbles. The tank is only used for skimming solids and therefore can be very small.

The GEM footprint is 30 – 90% smaller than a conventional DAF’s footprint for the same throughput.

GEM® System Advantages

- Better contaminant removal rates than DAF systems.

- Adaptability – the GEM System adjusts to higher flow rates and higher contaminant levels without equipment changes.

- Less chemicals – uses 20%-80% less chemicals than DAF systems.

- Smaller Footprint – uses less space than other flotation and flocculation systems.

- Drier Sludge – the technology of using long chain polymers produces drier sludge (8 to 13% drier and over 20% after decanting.)

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Water Clarification