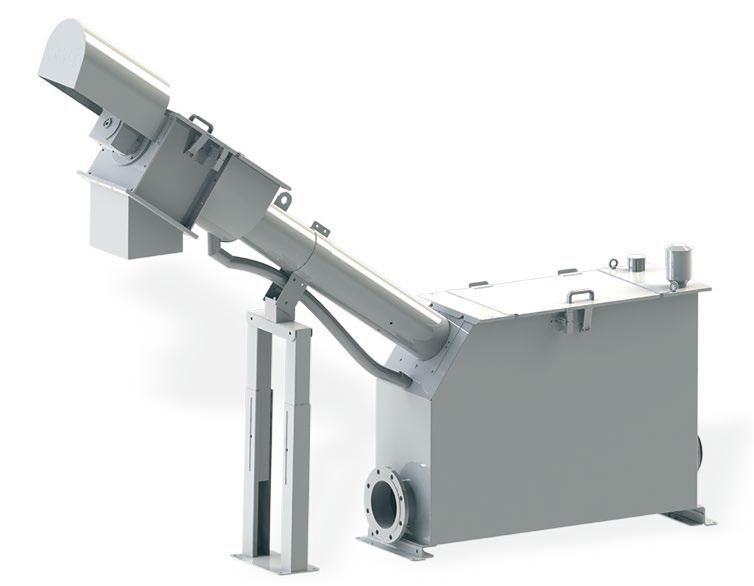

Screw Screen in Tank

The packaged Screw Screen in Tank (Product ID: SSB) provides primary treatment for untreated sewage and a wide range of industrial wastewater. It incorporates a screw screen that is mounted in a stainless-steel tank with flanged inlet and outlet connections, which allows for easy installation.

The tank can be fitted with an optional integrated bypass chamber (as contingency if the main screen overflows) fitted with a manually cleaned screen. The Screw Screen in Tank has a self-cleaning screen basket, with brushes fitted along the screw that continuously remove debris from the screen element surface, ensuring high solids removal efficiency. The screen element is offered in two options, rounded holes ranging from 3 to 10 mm or wedge wire ranging from 0.25 to 3 mm.

It is available with or without a compaction system, which is designed to reduce the weight and volume of captured screenings by up to 50% after compaction. The integrated compactor, located at the end of the transport section, efficiently washes, compacts and dewaters the screenings. Due to small footprint, minimal civil works required, and ease of installation, the Screw Screen in Tank offers a simple and low-cost solution for small wastewater treatment applications and septage receival facilities.

Technical Specifications

Standard Specifications

| Parameter | Units | SSB-mK-110 | SSB-mK-160 | SSB-mK-260 | SSB-mK-390 | SSB-mK-610 | SSB-mK-830 | ||

| Treatment capacity*1 | With rounded holes (mm) | Ø3 | m3/h | 90 | 130 | 198 | 320 | 504 | 669 |

| Ø4 | 93 | 137 | 218 | 360 | 528 | 756 | |||

| Ø5 | 108 | 156 | 237 | 385 | 606 | 804 | |||

| Ø6 | 131 | 189 | 288 | 466 | 734 | 973 | |||

| Ø8 | 139 | 199 | 304 | 492 | 774 | 1027 | |||

| Ø10 | 143 | 206 | 313 | 508 | 799 | 1059 | |||

| With wedge wire(mm) | 0.25 | 33 | 47 | 72 | 116 | 184 | 243 | ||

| 0.5 | 64 | 92 | 140 | 228 | 359 | 475 | |||

| 1 | 112 | 160 | 245 | 396 | 623 | 827 | |||

| 2 | 155 | 222 | 339 | 549 | 864 | 1145 | |||

| 3 | 173 | 248 | 378 | 612 | 963 | 1277 | |||

| Dimensions | A | mm | 3,190 | 3,120 | 3,125 | 3,100 | 4,050 | 4,175 | |

| T | 2,250 | 2,250 | 2,250 | 2,250 | 2,600 | 3,135 | |||

| H | 1,500 | 1,750 | 1,950 | ||||||

| O | 175 | 205 | 235 | 255 | 300 | 360 | |||

| I | 220 | 250 | 285 | 315 | 380 | 440 | |||

| F | 2,160 | 2,300 | 2,350 | 2,350 | 2,900 | 3,300 | |||

| W | 430 | 480 | 600 | 650 | 720 | 870 | |||

| Inlet/outlet flange*2 | DN | 150 | 200 | 250 | 300 | 400 | 500 | ||

| Installed motor power, 3ph, 50hz | kW | 0.55 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | ||

| Screw gear reducer speed | rpm | 11 | 11 | 11 | 8 | 8 | 8 | ||

| Wash water: Screen basket / compaction zone (@3 bar) | L/min | 23 / 31 | 62 / 44 | ||||||

| Empty weight | kg | 400 | 440 | 480 | 570 | 900 | 990 | ||

*1Theoretical, calculated using clean water, *2Flanges are lap joint max 15mm thick with holes P16 according to AS4087.

Tech specs

Standard Inclusions and Options

| Equipment | Standard Supply | Optional Supply | ||

| Screw screen in tank | Rounded holes screen element, 5mm (standard) or 3, 4, 6, 8 or 10mm | ✓ | - | |

| Wedge-wire screen element 0.25, 0.5, 1, 2 or 3mm | ✓ | - | ||

| Integrated screenings compaction (can be deleted as an option), model changes from -mk to -ok | ✓ | - | ||

| Screen basket cleaning, bolted nylon brushes | ✓ | - | ||

| PE breathing valve on screen tank | ✓ | - | ||

| PVC pipe for returning liquid from compaction zone | ✓ | - | ||

| Squared outlet spout | ✓ | - | ||

| Bolted screenings compaction system cover | ✓ | - | ||

| Lifting eyebolts | ✓ | - | ||

| Nord drives with compact motor gearbox and cover guards | ✓ | - | ||

| Machine carpentry, inlet & outlet flanges, drive guards, anti-wear materials on screw and bypass chamber (where applicable) All bolts in A4(SS316) | SS304L | ✓ | - | |

| SS316L(recommended for coastal and corrosive environments) | - | ✓ | ||

| Bypass chamber with manual screen | Bar screen | 10mm spacing | ✓ | - |

| Rounded holes | 6 or 10mm | ✓ | - | |

| Custom | Other options on special request | - | ✓ | |

| Screw | High-carbon steel painted | ✓ | - | |

| SS304L | - | ✓ | ||

| SS316L | - | ✓ | ||

| Washing systems | Compaction zone only, with ½” manual valve | ✓ | - | |

| Compaction zone with ½” manual valve and screening basket with 1” manual valve | - | ✓ | ||

| Manifold for compaction zone and screening basket, with 1” manual valve | - | ✓ | ||

| Automatic Longopac bagging system for screenings with 1x 80m long bag with sun protection cover | - | ✓ | ||

| Overflow outlet (flanged) and/or odour extraction port (flanged) | - | ✓ | ||

| Extended tank for tilt-out screen maintenance | - | ✓ | ||

| Drive motor premium efficiency | IP55 | ✓ | - | |

| IP65 with thermistor overload protection | - | ✓ | ||

| Surface treatments*1 | ✓ | - | ||

*1Stainless steel parts: stripping with acid solution, passivation with glass particles, final surfaces cleaning with anti-dust oil. Carbon steel parts: sandblasting SA 2.5 for external anti-rust paint RAL 5015

| Instrumentation & Controls | Standard Supply | Optional Supply | |

| Safety limit switches for screen and compaction zone opening hatches | ✓ | - | |

| Screen tank level sensor | Conductive probe | ✓ | - |

| Ultrasonic | - | ✓ | |

| Solenoid valve kit(s) for washing system(s) 24VDC | - | ✓ | |

| Mechanical over-torque protection (backlash free-ball model) | - | ✓ | |

| Control panel to AS/NZS 3000, 316SS enclosure, IP56 for outdoor installation, supplied loose, field wiringbetween control panel and equipment by others | - | ✓ | |

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

A regional council in South East Queensland required replacement of the rotating biological contactors (RBC) installed at their sewage treatment plant as these had reached the end of their serviceable life. These RBCs were originally designed to treat unscreened settled sewage, but performance had deteriorated over time. MAK Water was selected to provide a mechanical inlet screen to treat raw sewage prior to primary settling, and to provide two RBCs to replace the existing six RBCs within the site’s hydraulic and footprint constraints. This proved to be a cost competitive and fit for purpose approach whilst achieving the plant’s licence conditions.

Imbil, Queensland

Screening & Grit Handling

Related Solutions

Compact Screen and Grit Removal Package

The Compact Screen and Grit Removal Package (Product ID: ICE) is a primary treatment machine that combines screening and grit removal in a single compact plant.

Compact Screw Screen

The Compact Screw Screen (Product ID: SSG) is an economical solution for screening of industrial wastewater or domestic sewage.

Grit Classifier

MAK Water’s Grit Classifier (Product ID: SAK) is used to separate grit (which can contain sand, gravel and other heavy solids) from municipal and industrial wastewater streams.

Grit Removal System

The Grit Removal System is designed to provide grit removal pre-treatment in a single packaged unit process.

Internally Fed Drum Screen

The Internally Fed Drum Screen is a free-standing unit designed for separating settling solids from wastewater using an internally fed rotating drum screen.

Rotary Drum Screen

The Rotary Drum Screen (Product ID: FTR) is designed to remove solids from industrial wastewater streams.