Sodium Hypochlorite Disinfection - Flow Paced

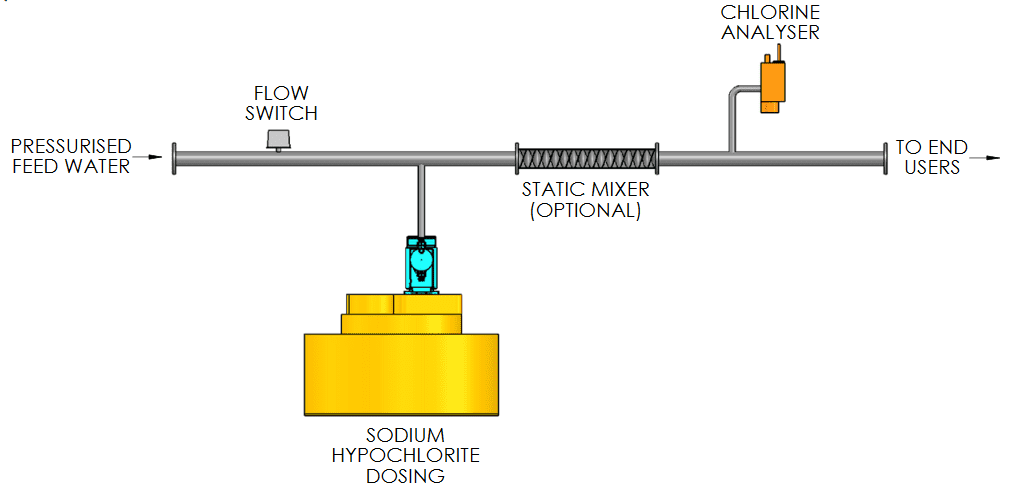

MAK Water’s Sodium Hypochlorite Disinfection Flow (SHDF) plants are designed to automatically maintain the correct amount of free chlorine in an existing reticulation line, in accordance with Australian Drinking Water Guidelines (ADWG). The standard sterilisation treatment process includes an inline chlorine analyser which monitors residual free chlorine and a dosing pump to automatically dose liquid sodium hypochlorite as required, into the potable or treated water pipeline.

The system components are sized to suit the required chlorine usage rate and the sodium hypochlorite storage tank refill frequency. Options are provided for duty standby dosing pumps to improve plant reliability, a flow transmitter, a static mixer if required to improve mixing. MAK Sodium Hypochlorite Disinfection Flow plants are available as either skid mounted for internal or external installations or containerised with air conditioning to avoid chlorine degradation.

.jpg)

Technical Specifications

Standard Specifications

Parameter | Units | SHSF-60 | SHSF-100 | SHSF-200 | SHSF-500 | SHSF-1000 | SHSF-2500 | SHSF-5000 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sodium Hypochlorite Storage Tank Size | L | 60 | 100 | 200 | 500 | 1,000 | 2,500 | 5,000 | ||||||||

| Free Chlorine Residual (target) | mg/L | 0.2 ~ 2 (as per Australian Drinking Water Guidelines ADWG) | ||||||||||||||

| Raw Water Temperature | °C | 15 ~ 35 | ||||||||||||||

| Ambient Design Temperature | °C | 5 ~ 35 (15 ~ 30 for insulated containerised system) | ||||||||||||||

| Raw Water Flow Rate | m³/hr | 0 ~ 1,000 | ||||||||||||||

| Raw Water Pressure | kPa | 0 ~ 800 | ||||||||||||||

| Power Supply | - | AC 240V, 1 phase, 50Hz or AC 415V, 3 phase, 50 Hz | ||||||||||||||

| Power Consumption (approx.) | kW | 0.5 | ||||||||||||||

| Container Size (optional) | ft | 1 x 10’ | 1 x 10’ | 1 x 10’ | 1 x 10’ | 1 x 10’ | 1 x 20’ | 1 x 20’ | ||||||||

Standard Inclusions and Options

Equipment | SHSF-60 | SHSF-100 | SHSF-200 | SHSF-500 | SHSF-1000 | SHSF-2500 | SHSF-5000 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Skid Mounted Plant | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Sodium Hypochlorite Dosing Pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Bunded Sodium Hypochlorite Storage Tank | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Chlorine Analyser | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Control System | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Alarm Signal Output for Client Interface | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Containerised Plant c/w A/C & Lights | o | o | o | o | o | o | o | |||||||||

| Container Non-slip Floor Coating | - | - | - | - | - | o | o | |||||||||

| Container Insulation (walls & ceiling) | o | o | o | o | o | o | o | |||||||||

| Container Side Access Door | - | - | - | - | - | o | o | |||||||||

| Duty Standby Dosing Pumps | o | o | o | o | o | o | o | |||||||||

| Flow Transmitter (existing reticulation line) | o | o | o | o | o | o | o | |||||||||

| Static Mixer | o | o | o | o | o | o | o | |||||||||

| Safety Shower & Eyewash Station | o | o | o | o | o | o | o | |||||||||

| Solar Power System | o | o | o | o | o | o | o | |||||||||

| Premium Instrumentation Package | o | o | o | o | o | o | o | |||||||||

Instrumentation | Standard Package | Premium Package | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Switch (existing reticulation line) | ✓ | ✓ | ||||||||||||||

| Float Switch (sodium hypochlorite storage tank) | ✓ | ✓ | ||||||||||||||

| Chlorine Analyser (4-20mA) | ✓ | ✓ | ||||||||||||||

| Level Transmitter (4-20 mA, sodium hypochlorite storage tank) | - | ✓ | ||||||||||||||

| Data Logger (residual chlorine) | - | ✓ | ||||||||||||||

| Remote Monitoring & Control Capabilities | - | ✓ | ||||||||||||||

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

The Balama Graphite project will be the leading global producer of high purity graphite. The front end engineering and design (FEED) was awarded to a Perth based engineering firm, who subsequently carried out the engineering and procurement for the project. As a reputable and renowned market leader in design and manufacture of packaged water and sewage treatment plants for the resources sector, MAK Water was awarded the contract to supply the project’s water and sewage treatment plants.

Balama, Mozambique

Chlorination System Upgrade for Corrective Services

A corrective service centre located near Geraldton in WA approached MAK Water to review the operations of their Wastewater Treatment Plant (WWTP). The current treatment process was not achieving the required standards set by the Department of Environment for its treated effluent, and therefore MAK Water’s objective was to provide a long-term solution that would not only improve water quality but reduce ongoing operation costs and promote operator safety. MAK Water was able to diagnose two main reasons the current system was failing, firstly inadequate contact time for the disinfectant to affectively work and the monitoring ability of the system to comply with DOH requirements. As the client did not want to have chlorine gas on site a sodium hypochlorite disinfection system was selected.

Geraldton, Western Australia

Water Disinfection Systems

Related Solutions

Chlorine Dioxide Generator HP Series

PureLine's HP series generator is ideally suited for applications that require high-purity Chlorine Dioxide, such as in food and beverage production, healthcare, and pharmaceutical manufacturing.

Chlorine Gas Disinfection Recirculation

Chlorine Gas Disinfection Recirculation (CGDR) Plants are designed to automatically maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG).

Sodium Hypochlorite Disinfection - Recirculated

Sodium Hypochlorite Disinfection Recirculated systems (SHDR) are designed to automatically maintain the correct amount of free chlorine in a potable water storage tank, in accordance with Australian Drinking Water Guidelines (ADWG).

UV Disinfection - Municipal

UV Disinfection - Municipal

UV Industrial

MAK Water’s UV Disinfection (UV) systems are an effective and economical means for disinfection of water.

Electrochorination

MAK Water offers an extensive range of onsite sodium hypochlorite generation plants and solutions as designed and manufactured by Electrolytic Technologies.