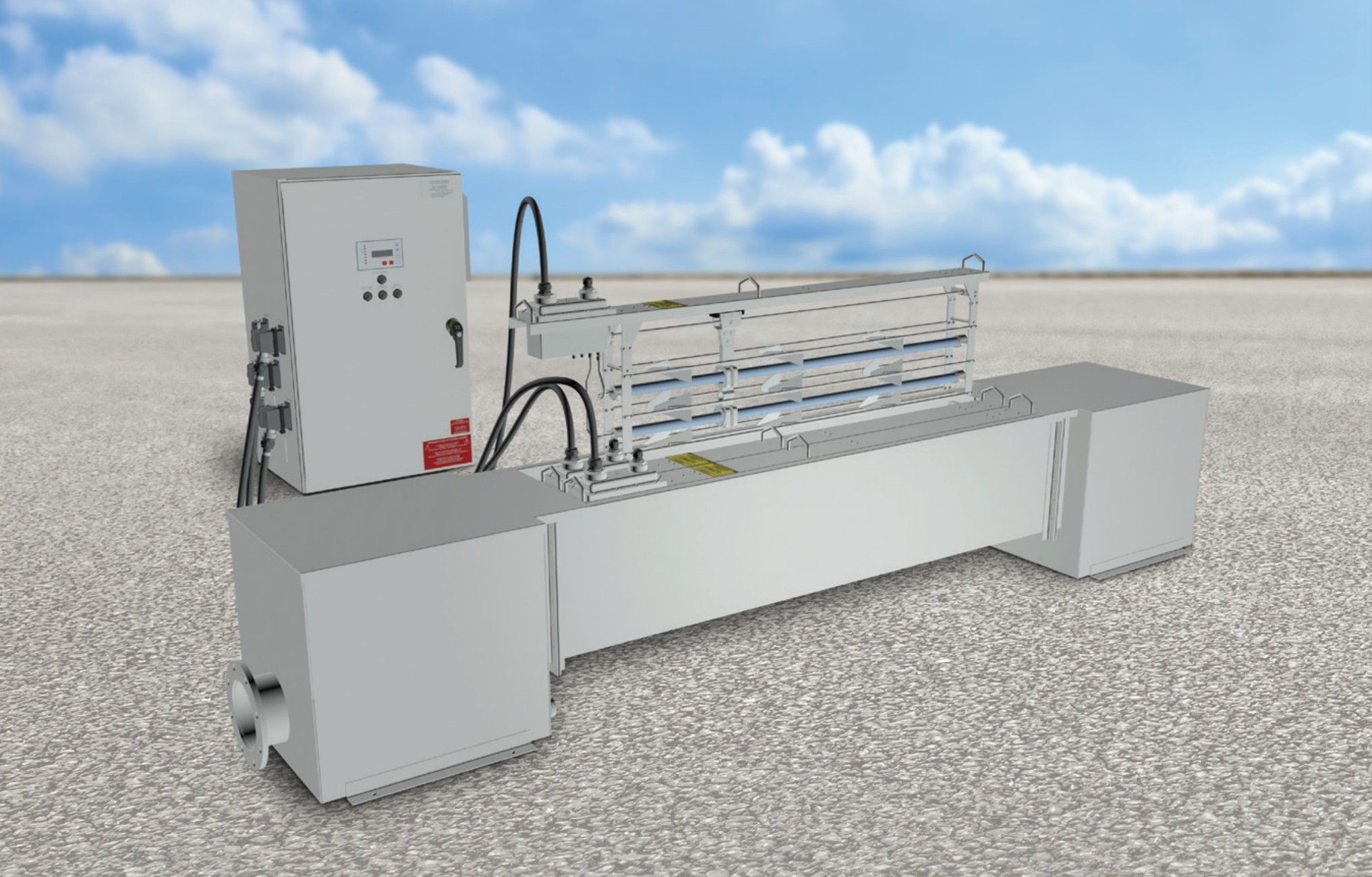

Sentinel® UV Reactors

UV disinfection with Sentinel UV systems provides a proven barrier to harmful pathogens that can be present in source water. This includes bacteria, viruses and chlorine-resistant protozoa such as Cryptosporidium and Giardia. All Sentinel UV reactors have undergone third party validation under the U.S. EPA LT2 Enhanced Surface Water Treatment Rule guidelines (USEPA UVDGM).

Sentinel UV reactors are available in various sizes and models accommodate pipe sizes from 12 to 48 inches (300 to 1200 mm) offering treatment from 1 to 196 ML/d per reactor.

Features and benefits:

- Municipal drinking water disinfection and Cryptosporidium and Giardia inactivation at a fraction of the cost of advanced technologies like ozone and membrane filtration

- Systems use electro-magnetic ballasts with excellent voltage tolerance to drive high-intensity Medium Pressure Lamps ranging from 4kW to 20kW

- Reactors use one UV intensity sensor per lamp for optimal dose and power control

- Reactors offer large turndown

- No disinfection by-products

- Outstanding taste and odour removal with the Advanced Oxidation Technologies of SENTINEL AOP

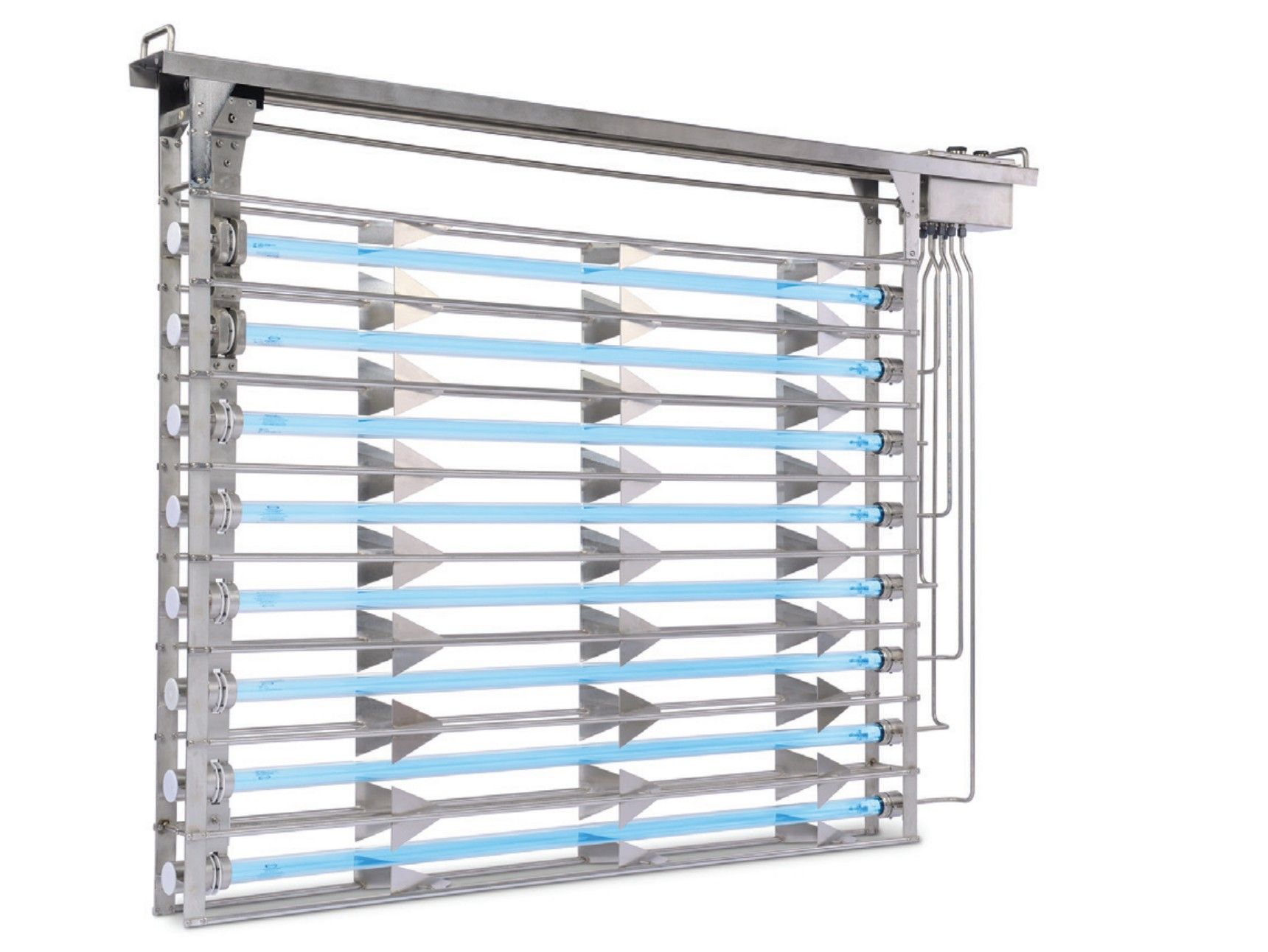

C3 Series In-Channel UV Systems

Available as packaged or engineered systems, the unique design of the C3500 UV system provides an open channel wastewater solution using fewer lamps and with reduced head loss.

The rack-mounted delta-shaped wings provide continual rotation and mixing of the effluent for uniform UV dose application from low-pressure, high-output (LPHO) amalgam lamps. The C3500 UV system is completely modular and scalable and can be precisely sized to any application requirement.

Features and benefits:

- Validated Performance: Rigorously bioassay-tested from 35% to 80% UVT using MS2 and T1 surrogates. Tested and certified for treatment requirements of the California Water Recycling Criteria (Title 22).

- Superior Disinfection Efficiency using fewer lamps than competing UV systems by use of LPHO amalgam lamps, with variable output from 60% to 100% and controlled mixing

- Smaller Footprint which offers lower overall cost of installation.

- Low hydraulic head loss design

- Mechanical self-cleaning system for quartz sleeves: electrically driven, stainless steel scrapers clean automatically without hazardous chemicals.

Applications

Real-world examples

Water Disinfection Systems

.jpg&w=1080&q=100)