Dewatering Screw Press

MAK Water’s Dewatering Screw Press (DSP) is designed for efficient thickening and dewatering of liquid sludges that emanate from municipal and industrial wastewater treatment processes. Typical applications for wastewater treatment plants include dewatering of thickened or unthickened waste activated sludge (WAS), digested sludge from aerobic or anaerobic processes, and dissolved air flotation (DAF) sludges.

Our Dewatering Screw Press is also suitable for dewatering of liquid sludges from a wide range of industries, including food & beverage, chemical, manufacturing, infrastructure development and resource industries.

For municipal WWTP sludge applications, our sludge Dewatering Screw Press typically produces dewatered sludge cake of 15% to 20% dry solids content. For industrial projects, depending on the specific application, cake of >20% dry solids content is possible.

The ability to dewater WAS directly from the activated sludge process, eliminates the need for an intermediate thickening process, thus offering significant savings in capital and operating costs.

Dewatering Screw Press Equipment Description

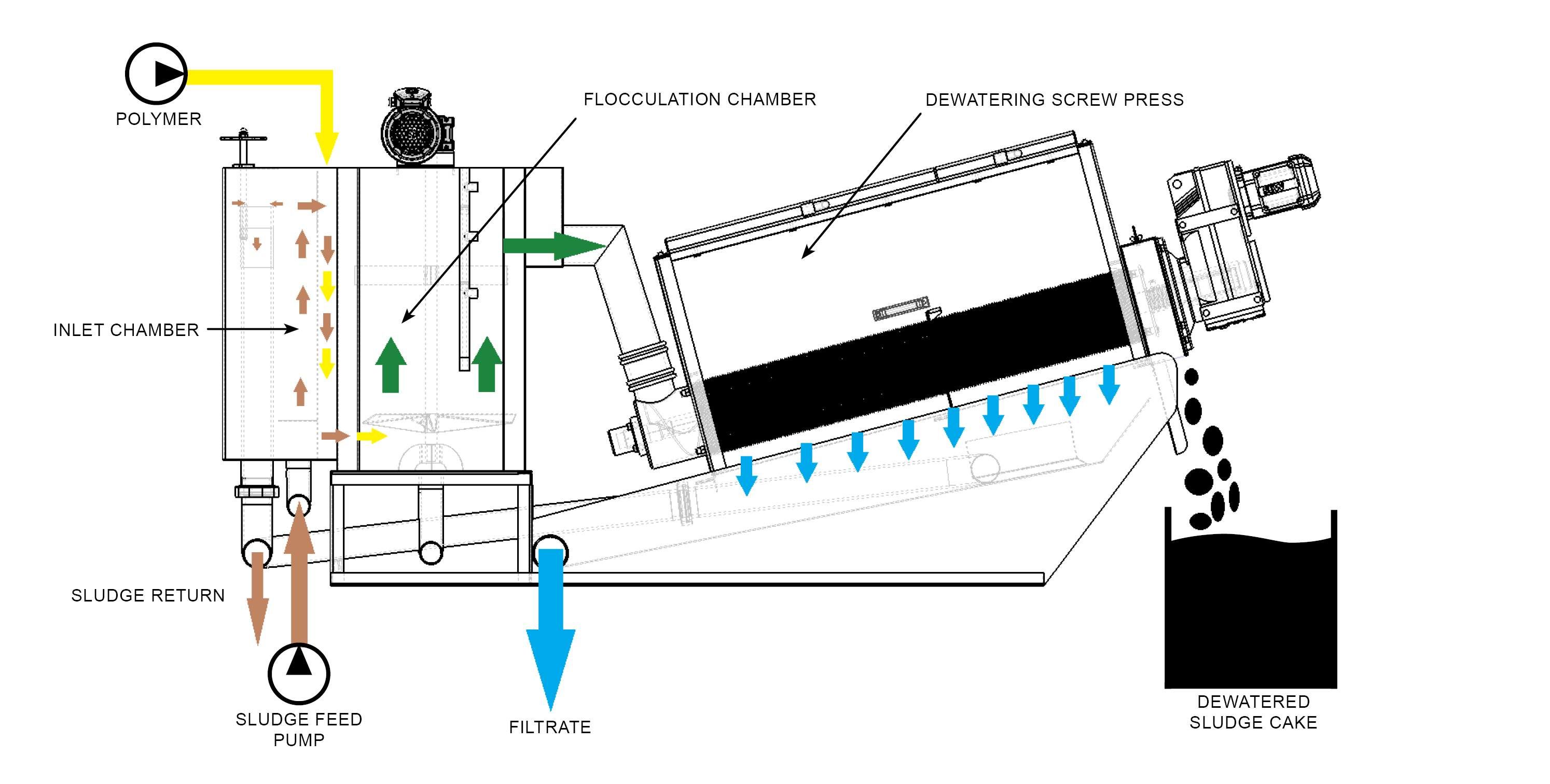

Liquid sludge is pumped to the Dewatering Screw Press via an external feed pump. The sludge enters the Inlet Chamber, which is fitted with an overflow. Any overflow is directed back to the sludge source tank or process. The Inlet Chamber serves to optimise flow to the other parts of the machine.

Liquid sludge is discharged from the Inlet Chamber via a V-notch weir into the Flocculation Chamber. Polymer is added into the Flocculation Chamber to aggregate/flocculate sludge solids into flocs. Flocculation occurs where the sludge and polymer are mixed slowly by a vertical paddle mixer. The sludge flocs then flow via an overflow from the Flocculation Chamber into the screw, which is the basic mechanism of the dewatering press.

A screw with a variable pitch helix operates within a cylinder of fixed and moving rings that make up the dewatering drum. The fixed rings form a static structure whereas the moving rings ensure continuous self-cleaning while the screw is in motion. The gap between the fixed and moving rings varies from 0.5 to 0.1 mm.

However, when the screw is in operation, the size of the gaps changes continuously, thus giving a smooth dewatering process. The filtrate that results from the dewatering process as the flocculated sludge is compressed, flows through these gaps into a collection tray located under the machine. The filtrate can gravitate from this tray to the head of works or any other suitable location.

An adjustable pressure plate is mounted at the end of the screw. This allows the already dewatered sludge to be compressed even more to increase the dewatering efficiency, thus producing dewatered sludge cake. The dewatered cake can be discharged from the sludge Dewatering Screw Press into a skip directly, or discharged via a conveyor into a skip for collection & disposal of the dewatered cake.

The Dewatering Screw Press machine is made of 304 stainless steel. The rings are made of 316 stainless steel, and the screw is made of 316L stainless steel with special tungsten surface treatment. This ensures abrasion resistance, sufficient hardness and resistance to wear and tear, and provides the necessary resistance to corrosion for materials which come into contact with aggressive sludges.

Equipment Operation & Control

The Dewatering Screw Press is designed to run in AUTO mode, thus requiring little operator attendance. In AUTO mode the operator can check the status of the equipment and change operational set-points via the HMI touch screen located in the Control Panel.

The Screw motor is fitted with a Variable Speed Drive (VSD) which makes it possible to accelerate or slow down the screw rotational speed for optimal dewatering. The Mixer motor is also fitted with a VSD to allow the operator to optimise flocculation for the best possible dewatering results.

The Dewatering Screw Press can also be operated in full MANUAL mode, where each component can be manually turned on/off via the HMI touch screen.

Key Features

- Single-step dewatering from as low as 0.2% dry solids content to 15-20%DS cake (WWTP sludges)

- High recovery rate >95%

- Simple installation and small footprint

- Simple automatic (or manual) operation

- Low energy consumption

- Low wash water consumption

- Simple and low maintenance

- Low noise and vibration levels

- Suitable for a wide range of applications

- High quality workmanship

- Control Panel compliant with AS/NZ 3000

Standard Specifications

Notes:

1) Depending on specific sludge type, polymer type and polymer dose, 20% or greater additional throughput may be possible.

2) Depending on specific sludge type and polymer type, the typical polymer consumption for feed sludge concentration 2 - 5 g/L is 4-8 kg/tonne dry solids processed, and for feed sludge concentration 5 - 50 g/L is 10-25 kg/tonne dry solids processed.

3) Compressed air requirements: min 5 - max 10 bar, quality as per ISO 8573-1:2010 including particple class <5, water content <7, oil content <3

4) SEW Eurodrive (Front Transmission Gearbox)

5) Motive (Worm-Transmission Gearbox)

"F" denotes flanged connection

Standard Inclusions + Options

1 Can include Polymer Preparation System and Cake Conveyor

2 Refer to MAK Water’s Product Datasheet for Polymer Preparation System (ASP)

3 Including discharge chute between DSP and Screw Conveyor.

Disclaimer: MAK Water is continuously updating and improving its products and services, please contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained within this document.

Hire