Key Features

Superior Energy Efficiency

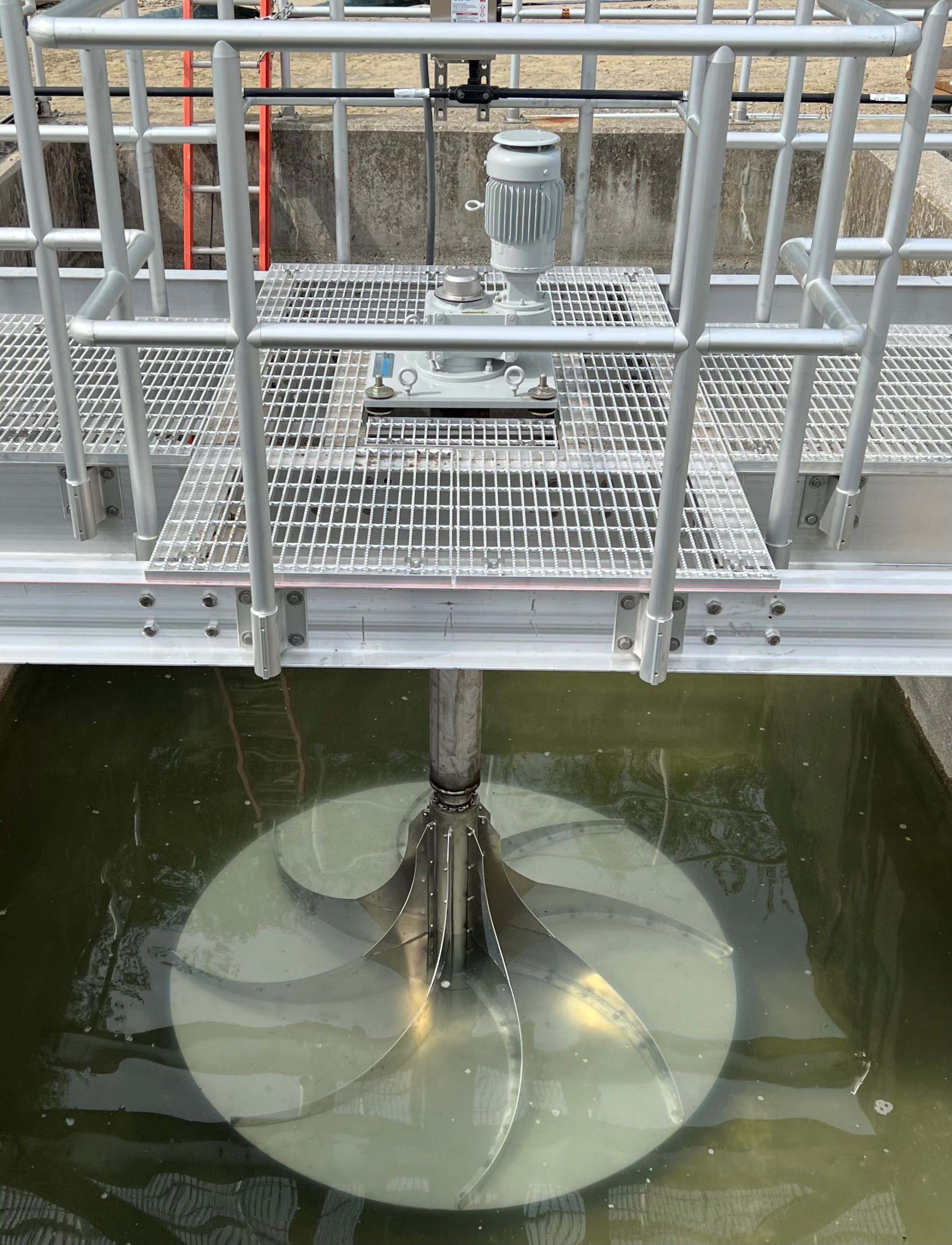

The Hyperbolic Mixer is engineered to minimise energy consumption while maximising water movement. Its backwards-curved pump blades are specifically designed to move large volumes of water with minimal power input. Additionally, the high-efficiency speed reducer minimises power losses, resulting in optimum conversion of power input into water mixing energy.

Exceptional Durability and Reliability

The Hyperbolic Mixer is built for longevity and high performance. The speed reducer is selected with a service factor that exceeds 100,000 hours of calculated life, ensuring long-term reliability. Heavy-duty output bearings provide robust support against all loads imposed by the rotor, eliminating the need for a lower guide bearing. The oversized drive shaft and sturdy mounting base minimise lateral rotor deflection and vibrations, ensuring stable and consistent operation.

High-Quality Materials for Corrosion Resistance

All wetted parts are manufactured from AISI 304 or AISI 316 stainless steel to provide excellent corrosion resistance in demanding environments. For applications involving highly saline or aggressive wastewaters, special coatings and materials are available to further enhance durability and performance. These include Super Duplex stainless steel, FRP, Carbon Fiber, Aluminium and Nickel/Monel.

Customisation Options

The Hyperbolic Mixer is available in standard configurations ranging from 0.75 to 22 kW. For projects with unique requirements, custom designs can be provided to ensure the mixer meets specific process needs. Using a customer’s tank design details, Computational Fluid Dynamics (CFD) analysis can be used to simulate and demonstrate the mixing performance of the Hyperbolic Mixer.

With its proven performance and advanced design, it meets the needs of modern water and wastewater treatment while supporting sustainable operations. The Hyperbolic Mixer is the ideal choice for facilities looking to enhance efficiency, reduce energy consumption, and ensure reliable operation in demanding environments.

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Aeration & Mixing