Technology Overview

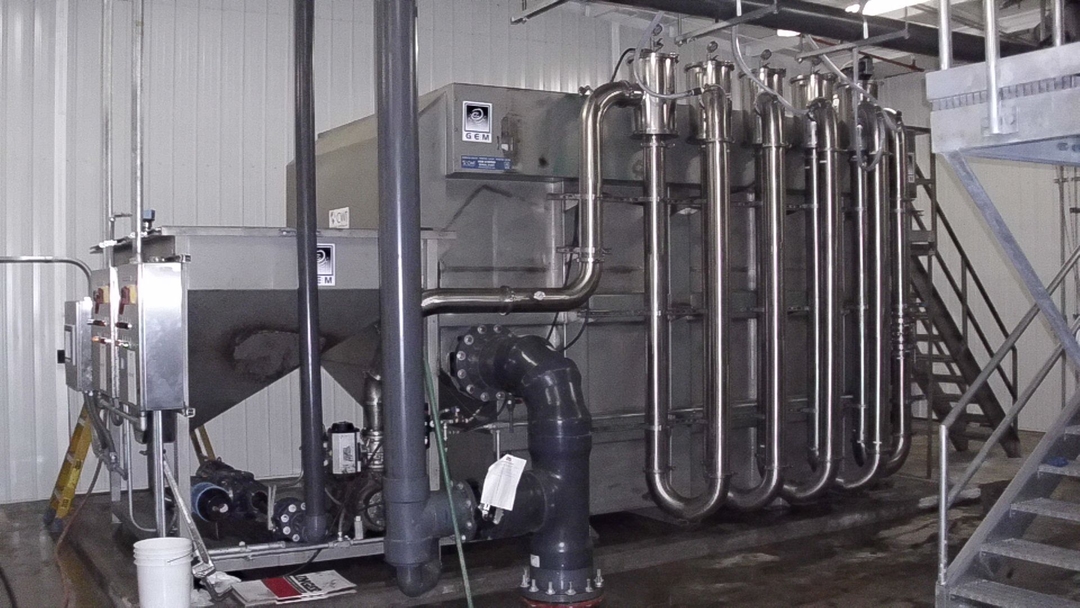

Lamella clarifiers can manage feed water with high concentration of suspended solids. Separation results will vary depending on the feed water quality and types of contaminants. The feed water enters the lamella clarifier through the inlet channel on the top and flows to the bottom of the separator. The water is led back to the top, on its way the water flows through the lamellas, onto which the solid particles settle.

Treated water flows to the top and reaches the outlet by passing a weir. The sludge slides down the lamellas and is collected in the sludge funnel. A rabble rake can be installed to prevent caking of the sludge in the conical hopper. The sludge is exported at intervals.

Key Features

Lamella Clarifiers are suitable wherever high levels of suspended solids or flakes are present and require separation from liquids.

- Gravel and sand industry

- Recycling industry

- Glass / Ceramics / natural stone

- Chemical industry

- Energy industry / cooling water

- Tunnelling / construction sites

- Waste / Landfill / street-cleaning

- Heavy metal precipitation

- Municipal water treatment Systems

- Wet scrubber and slaking effluents in the power industry

- Thickening processes in the chemical, mining and mineral industries

Technical Specifications

Standard Specifications

*1Based on 50mm plate spacing *2Based on 0.5 ~ 1.0m/hr settling rate *3Based on solids settling volume <10% *4Based om 0.05 ~ 0.2mL/L dose rate *5Optional Equipment

Standard Inclusions and Options

*1 Refer to Product Datasheet for Polymer Preparation System (ASP)

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Water Clarification