Activated Sludge Bioreactor

MAK Water’s Activated Sludge Bioreactor (ASBR) type packaged sewage treatment plants are designed to treat domestic strength sewage, to achieve “Class C” treated effluent, suitable for reuse in “risk category low” applications or for discharge to environment. With the optional “Class A” upgrade, treated effluent suitable for reuse in “risk category medium” applications is achieved.

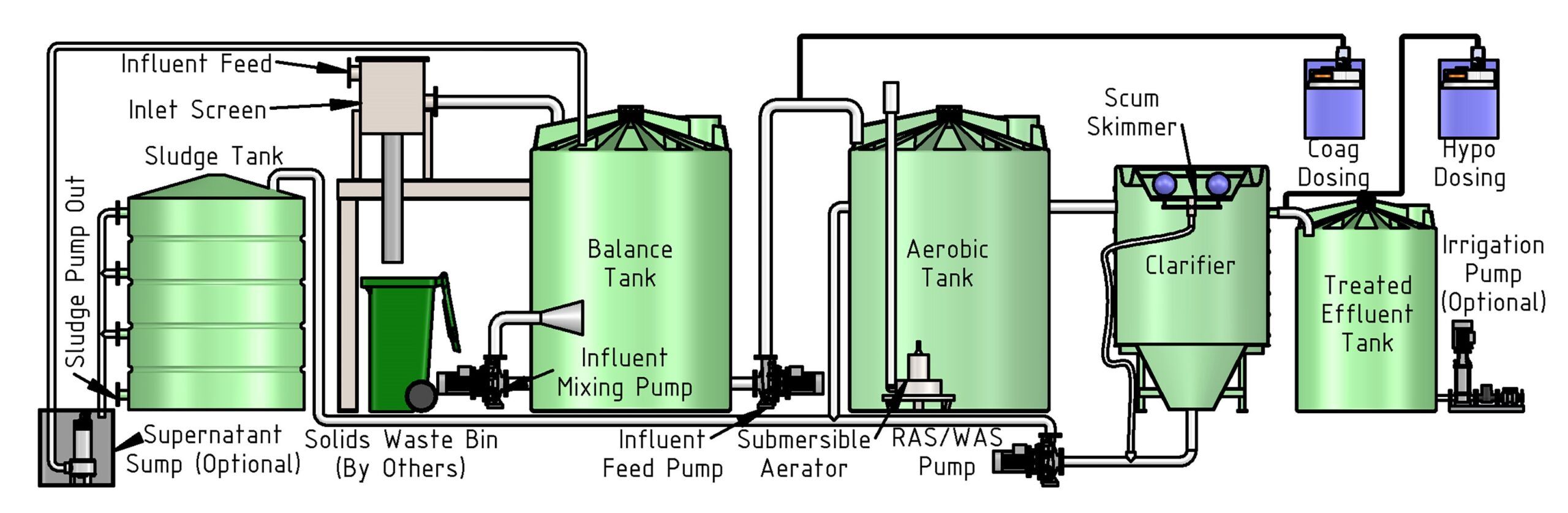

The standard treatment process includes influent screening, balance tank mixing, aerobic treatment, clarification and effluent disinfection (chlorine tablets). The optional “Class A” upgrade includes an auto-backwashing media filter, disinfection via tank recirculation and hypochlorite dosing, and analysers for online monitoring of treated effluent turbidity, free chlorine and pH.

MAK Water’s ASBR Bioreactors are corrosion resistant and are self-contained, modular systems for easy deployment to remote locations.

Tech specs

Standard

Parameter | Units | ASBR-025 | ASBR-035 | ASBR-050 | ASBR-070 | ASBR-100 | |

|---|---|---|---|---|---|---|---|

| Treatment capacity | m3/day | 25 | 35 | 50 | 70 | 100 | |

| *1Balance tank volume (recommended) | m3 | 25 | 35 | 50 | 70 | 100 | |

| *1Treated effluent tank volume (*2minimum) | m3 | 4.0 | 5.5 | 8.0 | 11 | 16 | |

| Sludge tank volume | m3 | 5.3 | 5.3 | 10.5 | 10.5 | 23 | |

| Thickened Sludge waste volume | m3/day | 0.3 | 0.4 | 0.5 | 0.8 | 1.2 | |

| *3 Irrigation pump duty | m3/hr @ 350 kPa | 2.1 | 2.9 | 4.2 | 5.8 | 8.3 | |

| Ambient temperature (min/max) | °C | 1 ~ 35 (1 ~ 43 with optional plant room air-conditioner) | |||||

| Power supply | - | AC 415 V, 3 Phase, 50 Hz | |||||

| Power consumption | Class C (max) | kW | 9 | 12 | 15 | 20 | 28 |

| Class A (max) | kW | 16 | 19 | 22 | 27 | 35 | |

| *3Irrigation pump motor size | kW | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | |

| *3Air conditioner | kW | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Footprint | FRP bioreactor & access platform | m | 6 x 3.2 | 7.5 x 3.2 | 9 x 3.2 | 12 x 3.2 | 10 x 3.8 |

| Sludge tank | Øm | 1.8 | 1.8 | 2.45 | 2.45 | 3.83 | |

Characteristics | Units | Influent | * 4 Class C Effluent | * 4 Class A Effluent | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature | °C | 15~35 | - | ||||||||||||||||||||||

| pH | pH units | 6.5~8.5 | 6.5~8.5 | ||||||||||||||||||||||

| Biological oxygen demand (BOD) | mg/L | *5≤350 | <20 | ||||||||||||||||||||||

| Suspended solids (TSS) | mg/L | *5≤350 | <30 | ||||||||||||||||||||||

| Oil & grease | mg/L | <10 | - | ||||||||||||||||||||||

| Total nitrogen (T-N) | mg/L | ≥20 | N/A (no reduction) | ||||||||||||||||||||||

| Total phosphorus (T-P) | mg/L | <16 | 4~12 (variable according to coagulant dose rate) | ||||||||||||||||||||||

| Total dissolved solids (TDS) | mg/L | <2,000 | - | ||||||||||||||||||||||

| Turbidity | NTU | - | N/A | <5 (95%ile) | |||||||||||||||||||||

| E.Coli | cfu/100 mL | - | <1,000 | <10 | |||||||||||||||||||||

| Free chlorine | mg/L | - | 0.2~2.0 | ||||||||||||||||||||||

*1 Sold Separately, *2 For 15 min.mg/L contact time, *3 Optional Equipment, *4 Based on QLD Guidelines, *5 Referenced from Metcalf & Eddy (5th edition, 2014), Typical composition of untreated domestic wastewater; higher/lower design values available on request.

Tech specs

Standard Inclusions + Options

Equipment | ASBR-025 | ASBR-035 | ASBR-050 | ASBR-070 | ASBR-100 | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Automatic inlet screen (2 mm) | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Influent mixing pump | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Influent feed pump | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| FRP bioreactor with aluminium access platform & ladder | Aerobic zone with submersible aerator | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||||||

| Clarifier with scum removal system | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Buffer zone/tank with tablet chlorinator | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Bioreactor roofing (COLORBOND® steel sheeting) | o | o | o | o | o | ||||||||||||||||||||

| Plant room with overhead lighting and GPO for maintenance | Chemical dosing – coagulant | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||||||

| RAS/WAS pump | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Effluent transfer/filter feed pump | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Class A | Auto-backwashing media filter | o | o | o | o | o | |||||||||||||||||||

| Treated effluent tank recirculation pump | o | o | o | o | o | ||||||||||||||||||||

| Hypochlorite dosing | o | o | o | o | o | ||||||||||||||||||||

| PLC control system with HMI | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Plant room air conditioner | o | o | o | o | o | ||||||||||||||||||||

| Sludge tank with supernatant sampling points and discharge valves | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||||||||

| Supernatant sump with submersible pump and level control | o | o | o | o | o | ||||||||||||||||||||

| Irrigation pump with level control and mechanical flow totaliser | o | o | o | o | o | ||||||||||||||||||||

| Instrumentation | Standard package | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||||||||

| Premium package with ClearAccess™ remote monitoring | o | o | o | o | o | ||||||||||||||||||||

Instrumentation & Controls | Standard Package | Premium Package | |

|---|---|---|---|

| Level switches | Balance tank | ✓ | - |

| Sludge tank | ✓ | ✓ | |

| Chemical dosing tank(s) | ✓ | ✓ | |

| Supernatant sump (optional) | ✓ | ✓ | |

| Level transmitters | Balance tank | - | ✓ |

| Buffer tank | ✓ | ✓ | |

| Treated effluent tank | ✓ | ✓ | |

| Flow switches | Effluent transfer pump (Class C) | - | ✓ |

| Treated effluent recirculation pump (Class A) | - | ✓ | |

| Irrigation pump (optional) | - | ✓ | |

| Pressure switches | Balance tank mixing pump | ✓ | ✓ |

| Pressure indicators | Balance tank mixing pump | ✓ | ✓ |

| Influent feed pump | ✓ | ✓ | |

| RAS/WAS pump | ✓ | ✓ | |

| Effluent transfer pump (Class C) | ✓ | ✓ | |

| Media filter feed pump (Class A) | ✓ | - | |

| Media filter discharge (Class A) | ✓ | - | |

| Irrigation pump (optional) | ✓ | ✓ | |

| Treated effluent recirculation pump (Class A) | ✓ | ✓ | |

| Pressure transmitter | Media filter feed pump (Class A) | - | ✓ |

| Media filter discharge (Class A) | - | ✓ | |

| Mechanical flow totaliser | Irrigation pump (optional) | ✓ | ✓ |

| Free chlorine and pH analyser (Class A) | ✓ | ✓ | |

| Turbidity analyser (Class A) | ✓ | ✓ | |

| ClearAccessTMremote monitoring & control capabilities | - | ✓ | |

Applications

Real-world examples

The Balama Graphite project will be the leading global producer of high purity graphite. The front end engineering and design (FEED) was awarded to a Perth based engineering firm, who subsequently carried out the engineering and procurement for the project. As a reputable and renowned market leader in design and manufacture of packaged water and sewage treatment plants for the resources sector, MAK Water was awarded the contract to supply the project’s water and sewage treatment plants.

Balama, Mozambique

The EPC contractor for Australia’s first dual open-cut kaolin mine and geological waste repository required a suitable sewage treatment plant to treat sewage from the accommodation camp and admin office. MAK Water was selected to provide a complete design, manufacture, and installation package for the new sewage treatment plant. MAK Water worked closely with the client to design a fit for purpose, long term solution that meets the required treated effluent quality.

Goldfields-Esperance, Western Australia

The owner of a new iron ore mine in Yilgarn, Western Australia required water treatment facilities for potable water, sewage treatment and heavy vehicle (HV) washbay wastewater treatment. MAK Water worked closely with the client to design a custom package of four (4) separate plants, providing the best possible water treatment solutions across the entire mine site. MAK Water supplied a potable water treatment plant located at the iron ore mine to treat hypersaline bore water; a sewage treatment plant located at the camp; HV washbay wastewater treatment for removal of hydrocarbons; and additional disinfection and pH adjustment for water reuse in the washbay.

Goldfields-Esperance, Western Australia

One of the large global mining and processing companies was developing a new mine to extend the life of their Weipa bauxite operations by a planned four decades. MAK Water was engaged by the global Engineering, Construction, and Project Management Company (EPCM) contractor to design and construct the sewage treatment plant for the mine infrastructure area (MIA). The plant was constructed according to project engineering and design specifications, using project preferred electrical equipment, and supplied with site specific vendor drawing and data package. MAK Water provided site installation support and commissioning of the plant.

Queensland

Wastewater & Sewage Treatment Plants

Related Solutions

Activated Sludge Bioreactor Plus

MAK Water’s Activated Sludge Bioreactor Plus (ASBR+) type packaged sewage treatment plants are designed to treat domestic strength sewage, to achieve “Class C” treated effluent, plus enhanced nutrient removal, suitable for reuse in “risk category low” applications or for discharge to environment.

Biocombi

MITA Water Technologies’ compact Biocombi plants offer an ideal solution for small to medium residential areas.

Membrane Bioreactor

MAK Water’s Membrane Bioreactor (MBR) type packaged sewage treatment plants are designed to treat domestic strength sewage, to achieve “Class A+” treated effluent, suitable for reuse in “risk category high” applications or for discharge to sensitive environments.

Moving Bed Bioreactor

MAK Water’s Moving Bed Bioreactor (MBBR) type packaged sewage treatment plants are designed to treat domestic strength sewage, to achieve “Class C” treated effluent, suitable for reuse in “risk category low” applications or for discharge to environment.

Moving Bed Bioreactor Plus

MAK Water’s Moving Bed Bioreactor Plus (MBBR+) type packaged sewage treatment plants are designed to treat domestic strength sewage, to achieve “Class C” treated effluent, plus enhanced nutrient removal, suitable for reuse in “risk category low” applications or for discharge to environment.

Rotating Biological Contactor

The Rotating Biological Contactor (RBC) system is a compact, efficient wastewater treatment solution.