pH Adjustment - Batched

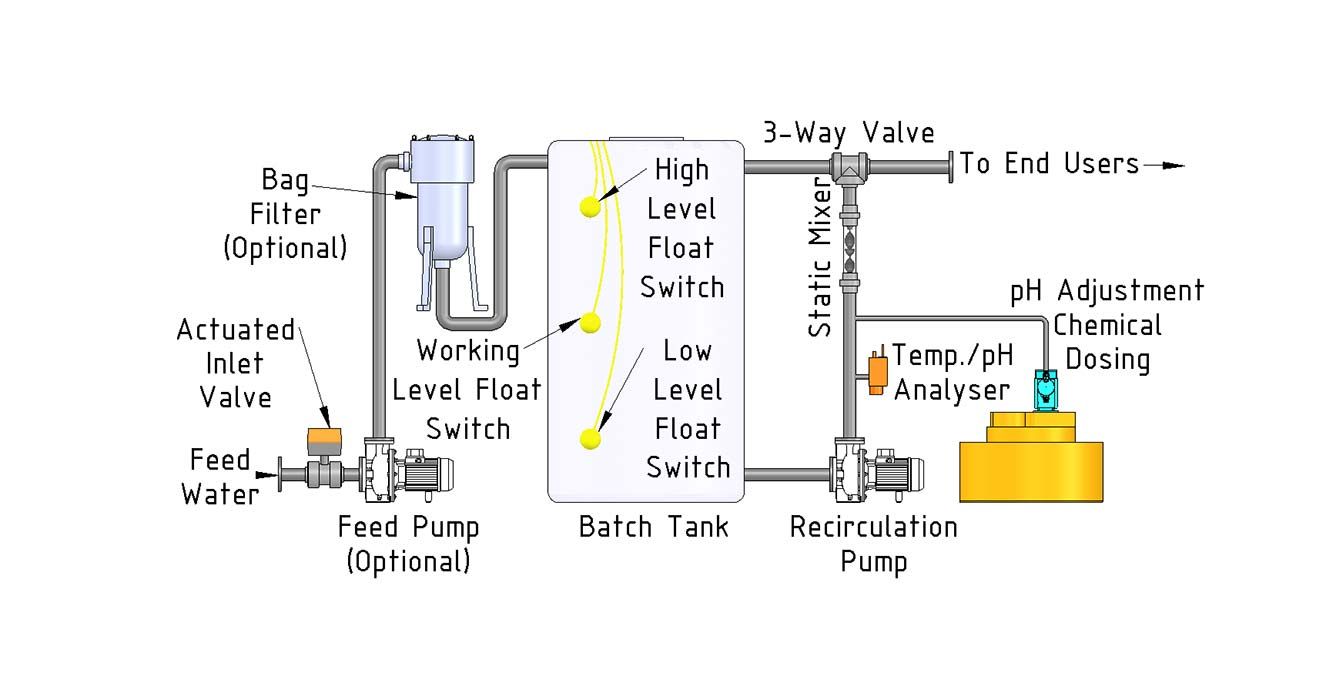

pH Adjustment - Batch (PAB) plants are designed to automatically adjust and maintain the pH level of wastewater in a batch tank prior to discharge to sewer/ environment or reuse/recycling. The standard treatment process includes a batch tank, a recirculation pump to turn over the contents of the batch tank, a temperature sensor, an inline pH analyser which monitors the pH level and a dosing pump to automatically dose liquid alkali and/or acid. The recirculation pump is also used to discharge the treated water at the end of each batch cycle. Dual chemical dosing pumps (alkali and acid) are available for when the water pH varies to allow for correction of both low and high pH water.

The system components are sized to suit the batch tank and to allow for a 30-60 minute complete batch cycle. Optional equipment upgrades include; a feed pump, bag filter, duty standby recirculation and dosing pumps, materials upgrade for high/low pH levels, dual chemical dosing pumps (alkali and acid). MAK Water’s PAB plants are available as skid mounted or containerised systems for easy deployment to remote locations.

Technical Specifications

Standard Specifications

Parameter | Units | PAB-1 | PAB-2 | PAB-5 | PAB-10 | PAB-15 | PAB-22 | PAB-30 |

|---|---|---|---|---|---|---|---|---|

| Batch Tank Size | m³ | 1 | 2.45 | 5 | 10 | 15 | 22.5 | 30 |

| Batch Cycle Time | min | 30- 60 | ||||||

| Recirculation Pump Flow Rate | L/min | 100 | 165 | 335 | 650 | 1,100 | 1,500 | 2,000 |

| Recirculation Discharge Pressure | mH2O | 15 ~ 25 | ||||||

| Dosing Pump Flow Rate | L/h | 10 | 20 | 30 | ||||

| pH Level (target) | pH | 6 ~ 8 (pH neutral) or as required | ||||||

| pH Range (influent) | pH | 4 ~ 12 (1 - 14 optional) | ||||||

| Alkalinity (assumed) | mg/L as CaCO3 | 10 (consult MAK Water if higher influent alkalinity is expected) | ||||||

| Particle Size | mm | ≤2 (consult MAK Water if larger particles or debris are expected) | ||||||

| Total Suspended Solids | mg/L | 1,000 (<50 with optional bag filter) | ||||||

| Raw Water Temperature | °C | 1 - 40 | ||||||

| Ambient Design Temperature | °C | 0 - 45 | ||||||

| Power Supply | - | AC 240V, 1P, 50Hz or AC 415V, 3P, 50Hz | AC 415V, 3P, 50Hz | |||||

| Power Consumption (approx.) | kW | 1.1 | 1.5 | 3 | 4 | 7.5 | 11 | |

| Bunded Chemical Storage Tank | L | 110 | 210 | 600 | 1,000 | |||

| Container Size (optional) | ft | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Skid Size (excl. Tank) | mm | 1,300 x 600 x 1,500 | 2,000 x 1,500 x 1,500 | |||||

Standard Inclusions and Options

Equipment | PAB-1 | PAB-2 | PAB-5 | PAR-10 | PAB-15 | PAB-22 | PAB-30 |

|---|---|---|---|---|---|---|---|

| Skid Mounted Plant | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Batch Tank (standard pH range) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Recirculation Pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Chemical Dosing Pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Bunded Chemical Storage Tank | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Alarm Signal Output for Client Interface | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Automated Control System | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| PLC Control System with HMI | o | o | o | o | o | o | o |

| Containerised System, c/w A/C & Lights | o | o | o | o | o | o | o |

| Container Insulation (walls & ceiling) | o | o | o | o | o | o | o |

| Feed Pump | o | o | o | o | o | o | o |

| 100μm Bag Filter | o | o | o | - | - | - | - |

| Duty Standby Recirculation Pumps | o | o | o | o | o | o | o |

| Duty Standby Dosing Pumps | o | o | o | o | o | o | o |

| pH 1 - 14 Range Recirculation Pump | o | o | o | o | o | o | o |

| pH 1 - 14 Range Batch Tank | o | o | o | o | o | o | o |

| Dual Dosing Pumps (alkali/acid) c/w Dual Bunded Chemical Storage Tanks | o | o | o | o | o | o | o |

| Safety Shower & Eyewash Station | o | o | o | o | o | o | o |

| Premium Instrumentation Package | o | o | o | o | o | o | o |

Instrumentation | Standard Package | Premium Package |

|---|---|---|

| Pressure Gauge (pump discharge) | ✓ | ✓ |

| Pressure Gauge (optional Bag Filter discharge) | ✓ | ✓ |

| Flow Switch | ✓ | ✓ |

| Float Switch (batch tank & chemical storage tank) | ✓ | ✓ |

| pH Analyser (4-20 mA) | ✓ | ✓ |

| Data Logger (pH level) | ✓ | ✓ |

| Temperature Sensor | ✓ | ✓ |

| Level Transmitter (4-20 mA, batch tank & chemical storage tank) | - | ✓ |

| Remote Monitoring & Control Capabilities | - | ✓ |

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Trade Wastewater Treatment for Geological Laboratory

Laboratory services at Brisbane Airport needed to treat the wastewater from their on-site laboratories to ensure it could be safely and compliantly discharged to sewer.

Orange, New South Wales

Wastewater for Mining Laboratory

Newcrest Services needed to treat the wastewater from their on-site laboratories to ensure it could be safely and compliantly discharged to sewer.

Orange, New South Wales

Trade Wastewater Treatment For Laboratory

Laboratory services at Brisbane Airport needed to treat the wastewater from their on-site laboratories to ensure it could be safely and compliantly discharged to sewer. MAK Water proposed a Containerised pH Adjustment Batch System capable of treating up to 1,000l/h of acid wastewater.

Brisbane Airport, Queensland

pH Adjustment Hire Equipment

MAK Water was approached by a company reconditioning runways in Sydney to supply a short term solution for a wastewater stream with a very high pH. The company’s processes were creating approximately 20,000L of wastewater every day with a pH >12 that needed to be brought down to neutral prior to disposal. Due to the short-term nature of the job, it made sense to hire the equipment from MAK Water’s fleet of hire water treatment equipment rather than buy something.

New South Wales

pH Adjustment Batch for Manufacturing

MAK Water was approached by a large family-owned business in Sydney to provide a suitable solution to their increasing volumes of trade wastewater from their manufacturing process. The business was producing approximately 7-8 thousand litres a week of mildly acidic wastewater that they were paying to be disposed of by a liquid waste company as the pH was too low to be suitable for disposal into Sydney Water’s sewer system. The volumes being removed were relatively small compared to other companies so having a system that could meet the discharge specification and be cost effective was very important.

New South Wales

Chemical Dosing

Related Solutions

Chemical Dosing Skids

MAK Water’s Chemical Dosing (CD) skids are designed to automatically dose a chemical(s) into a pressurised pipeline.

pH Adjustment - Flow Paced

pH Adjustment – Flow Paced (PAF) plants are designed to automatically adjust and maintain the pH level of pressurised raw water prior to discharge to sewer/environment or reuse/recycling.

pH Adjustment - Recirculated

MAK Waters pH Adjustment - Recirculated (PAR) plants are designed to automatically adjust and maintain the pH level of raw water in a storage tank, prior to discharge to sewer/environment or reuse/recycling.