pH Adjustment - Recirculated

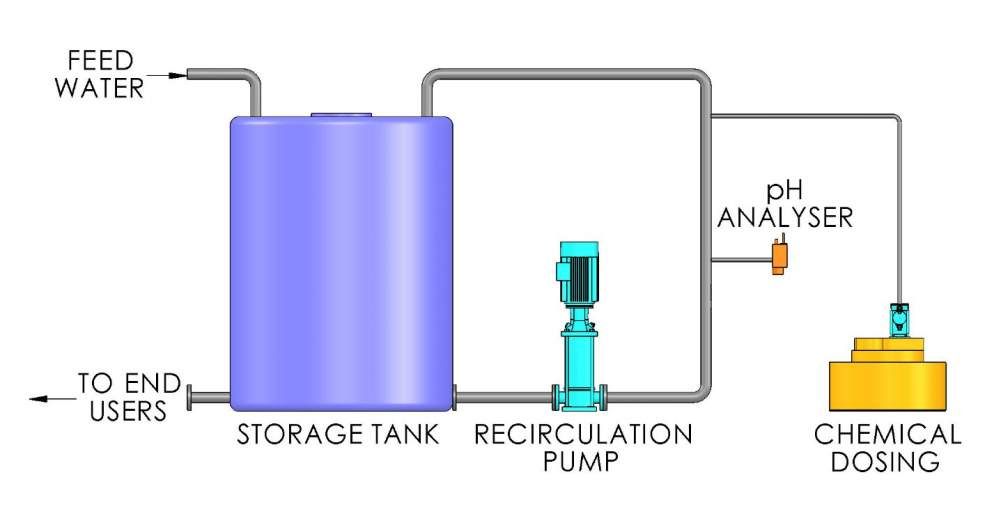

MAK Waters pH Adjustment - Recirculated (PAR) plants are designed to automatically adjust and maintain the pH level of raw water in a storage tank, prior to discharge to sewer/environment or reuse/recycling. The standard treatment process includes a recirculation pump to turn over the contents of the storage tank twice in a 24 hour period, an inline pH analyser which monitors the pH level and a dosing pump to automatically dose liquid alkali/acid. Dual chemical dosing pumps (alkali/ acid) are available for when the raw water pH varies to allow for correction of both low and high pH raw water.

The system components are sized to suit the storage tank and daily usage. Optional equipment upgrades include; duty standby recirculation and dosing pumps, high/low pH levels, dual chemical dosing pumps (alkali/acid). MAK PAR plants are available as skid mounted or containerised systems for easy deployment to remote locations.

Technical Specifications

Standard Specifications

Parameter | Units | PAR-10 | PAR-25 | PAR-50 | PAR-100 | PAR-250 | PAR-500 | PAR-1000 | PAR-2500 |

|---|---|---|---|---|---|---|---|---|---|

| Storage Tank Size (by others) | m³ | 10 | 25 | 25 | 100 | 250 | 500 | 1,000 | 2,500 |

| Recirculation Pump Flow Rate | m³/hr | 0.8 | 2 | 2 | 8.3 | 20.8 | 41.6 | 83.3 | 208.3 |

| Recirculation Pressure | kPa | 100 ~ 200 | |||||||

| pH Level (target) | pH | 6 ~ 8 (pH neutral) or as required | |||||||

| pH Range (standard) | pH | 4 ~ 12 | |||||||

| Raw Water Temperature | °C | 15 ~ 35 | |||||||

| Ambient Design Temperature | °C | 5 ~ 35 (-15 ~ 50 for insulated containerised system) | |||||||

| Feed Water Inlet Pressure | kPa | >15 (flooded suction) | |||||||

| Power Supply | - | AC 240V, 1 phase, 50Hz or AC 415V, 3 phase, 50Hz | AC 415V, 3 phase, 50Hz | ||||||

| Installed Power (approx.) | kW | 1 | 1 | 1 | 1.5 | 2.5 | 3.5 | 6 | 16 |

| Bunded Chemical Storage Tank | L | 200 | 200 | 200 | 500 | 500 | 1,000 | 1,000 | 1,500 |

| Container Size (optional) | ft | 10’ | 10’ | 10’ | 10’ | 10’ | 10’ | 10’ | 20’ |

| Skid Size | mm | 1,300 x 560 x 1,500 | 2,000 x 1,500 x 1,500 | ||||||

Standard Inclusions and Options

Equipment | PAR-10 | PAR-25 | PAR-100 | PAR-250 | PAR-500 | PAR-1000 | PAR-2500 | PAR-5000 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Skid Mounted Plant | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Recirculation Pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Chemical Dosing Pump | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Bunded Chemical Storage Tank | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| PLC Control System with HMI | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Alarm Signal Output for Client Interface | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Containerised System, c/w A/C & Lights | o | o | o | o | o | o | o | o | |||||||||

| Container Non-slip Floor Coating | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | o | o | |||||||||

| Container Insulation (walls & ceiling) | o | o | o | o | o | o | o | o | |||||||||

| Container Side Access Door | - | - | - | - | - | - | o | o | |||||||||

| Duty Standby Recirculation Pumps | o | o | o | o | o | o | o | o | |||||||||

| Duty Standby Dosing Pumps | o | o | o | o | o | o | o | o | |||||||||

| pH 1-12 Recirculation Pump | o | o | o | o | o | o | o | o | |||||||||

| Dual Dosing Pumps (alkali/acid) c/w Dual Bunded Chemical Storage Tanks | o | o | o | o | o | o | o | o | |||||||||

| Safety Shower & Eyewash Station | o | o | o | o | o | o | o | o | |||||||||

Instrumentation | Standard Package | Premium Package | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Gauge | ✓ | ✓ | |||||||||||||||

| Flow Switch | ✓ | ✓ | |||||||||||||||

| Float Switch (chemical storage tank) | ✓ | ✓ | |||||||||||||||

| pH Analyser (4-20 mA) | ✓ | ✓ | |||||||||||||||

| Level Transmitter (4-20 mA, chemical storage tank) | - | ✓ | |||||||||||||||

| Data Logger (pH level) | - | ✓ | |||||||||||||||

| Remote Monitoring & Control Capabilities | - | ✓ | |||||||||||||||

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Chemical Dosing

Related Solutions

Chemical Dosing Skids

MAK Water’s Chemical Dosing (CD) skids are designed to automatically dose a chemical(s) into a pressurised pipeline.

pH Adjustment - Batched

pH Adjustment - Batch (PAB) plants are designed to automatically adjust and maintain the pH level of wastewater in a batch tank prior to discharge to sewer/ environment or reuse/recycling.

pH Adjustment - Flow Paced

pH Adjustment – Flow Paced (PAF) plants are designed to automatically adjust and maintain the pH level of pressurised raw water prior to discharge to sewer/environment or reuse/recycling.