Background

The Balama Graphite project will be the leading global producer of high purity graphite. The front end engineering and design (FEED) was awarded to a Perth based engineering firm, who subsequently carried out the engineering and procurement for the project.

As a reputable and renowned market leader in design and manufacture of packaged water and sewage treatment plants for the resources sector, MAK Water was awarded the contract to supply the project’s water and sewage treatment plants.

Solution

The project required a raw water treatment plant to sterilise river water for use as process water, as well as potable water and sewage treatment plants.

MAK Water Key Solutions

RAW WATER TREATMENT PLANT

- Flow paced hypochlorite dosing to suit 288 m3 per hour

- Insulated and air conditioned container minimises hypochlorite heat degradation

- Dosing speed control by client eliminated PLC costs

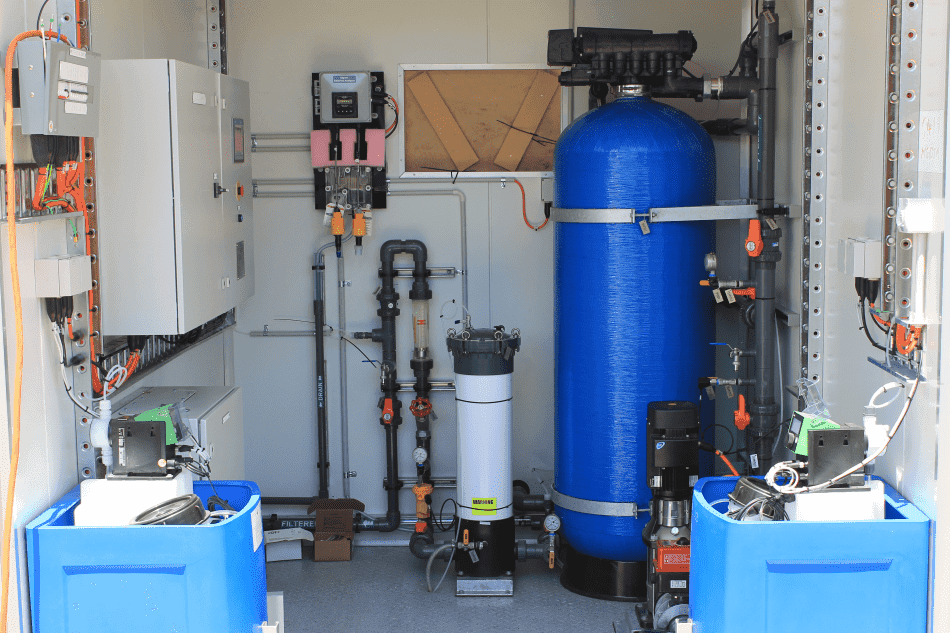

POTABLE WATER TREATMENT PLANT

- 170 m3 per day multimedia filtration plant with pH correction and residual trim hypochlorite dosing

- 10’ containerised plant, insulated and air conditioned

SEWAGE TREATMENT PLANT

- 50 m3 per day Activated Sludge Bioreactor (ASBR)

- Corrosion resistant fibre-reinforced plastic (FRP) bioreactor with internal plant room

- Seven off packaged sewage pump stations

Results and benefits

- Project specifications. Plants supplied with project preferred PLC and touch screen (HMI).

- Lower freight costs. ASBR fits into a 40’ shipping container for standard ocean freight.

- Plug and play. Pre-tested, containerised/modular design for fast and easy installation onsite.

Up next