Gravity Clarification

MAK Water’s Clearmake™ range of Gravity Clarification (GC) systems are designed to clean water prior to reuse, or discharge to the sewer or the environment. These systems help to minimise the use of potable water or town water supplies while protecting the users and the environment from contaminants in the waste stream. MAK Water’s, Clearmake™ treatment systems are compliant with local Council, DEHP, DAFF + OH&S requirements.

Gravity Clarification is the process of clarifying water by using a flocculant to coagulate the suspended solids into heavier particles which then settle to the bottom of a tank/ clarifier. Different contaminants can have different settling times so Gravity Clarification Systems are designed to suit specific flow rates and factor in parameters such as types of contaminants, volume and surface area.

MAK Water has a range of Clearmake™ Gravity Clarifiers to suit most flow rates, we are also able to custom design a treatment system to suit specific needs and contaminants. Some of the key benefits are very few moving parts, ability to manage continuous flow and capacity to treat a myriad of applications.

Standard Specifications

Parameter | Units | GC-700 | GC-1500 | GC-3000 | GC-5000 | GC-10000 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard Treatment Rate | L/hr | 700L | 1.5kL | 3kL | 5kL | 10kL | ||||||||||||

| Custom Flow Rates | L/hr | 10kL+ | ||||||||||||||||

| Sludge Volume | % | Up to 15 ~ 20 (varies according to feed water quality and system configuration) | ||||||||||||||||

| TSS Discharge | mg/L | <10 (typical) | ||||||||||||||||

| Filtrate Particle Size | microns | 25 | ||||||||||||||||

| TPH Discharge Levels | mg/L | <5 (typical) | ||||||||||||||||

| Raw Water Temperature | °C | 5 ~ 35 (typical) | ||||||||||||||||

| Ambient Design Temperature | °C | 5 ~ 45 | ||||||||||||||||

| Power Supply | V | 240v (single phase) ~ 415v (3 Phase) | ||||||||||||||||

| Power Consumption (approx.) | kW | 0.8 | 0.8 | 1.1 | 2.2 | 2.2 | ||||||||||||

| Footprint | m | 1.8 x 1.8 | 2.0 x 2.0 | 2.0 x 4.4 | 2.0 x 4.8 | 2.1 x 5 | ||||||||||||

Standard Inclusions and Options

Equipment | GC-700 | GC-1500 | GC-3000 | GC-5000 | GC-10000 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OWS Pre-treatment Package (OWS, Controller, Pump & WOR) | o | o | o | o | o | |||||||||||||

| Frame Mounted Plant & Equipment | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||

| Skid Mounted (standard on 700 Batch System) | ✓ | o | o | o | o | |||||||||||||

| PLC Control System with HMI | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||

| pH Adjustment | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||

| Flocculant dosing | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||

| Polymer dosing | - | ✓ | ✓ | ✓ | ✓ | |||||||||||||

| Clarification Tank | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||||||

| Bag Filter | ✓ | ✓ | ✓ | o | o | |||||||||||||

| Additional Post GC Treatment | Multimedia Filtration | - | o | o | o | o | ||||||||||||

| pH Correction | - | o | o | o | o | |||||||||||||

| Disinfection Dosing & recirculation module | - | o | o | o | o | |||||||||||||

| UV Disinfection | - | o | o | o | o | |||||||||||||

| Granular Activated Carbon (GAC) Filtration | - | o | o | o | o | |||||||||||||

| Sludge Pump System | o | o | o | o | o | |||||||||||||

| Premium Instrument Package | o | o | o | o | o | |||||||||||||

Instrumentation | Standard Package | Premium Package |

|---|---|---|

| Human Machine Interface (HMI) | ✓ | ✓ |

| Control Panel | ✓ | ✓ |

| Pressure Gauges | ✓ | - |

| Pressure Transmitters (4-20 mA) | - | ✓ |

| High Level Alarms | ✓ | ✓ |

| pH Transmitter 4 ~ 20mA | ✓ | ✓ |

| Flow Transmitters (4-20 mA) | - | ✓ |

| Float Switches (Feed/Treated Water Tanks, Chemical Dosing Tanks) | - | ✓ |

| Remote Monitoring & Control Capabilities | - | ✓ |

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Wash Down Wastewater Treatment for Marina Vessel

Akuna Bay Marina in NSW required a treatment system to treat the waste stream from the Marina hardstand. The waste stream comprised general wash down of vessels during servicing and hull cleaning processes. The site has no access to a sewer for trade waste discharge, so wastewater treatment was required to enable treated wastewater to be discharged to the environment.

Akuna Bay, New South Wales

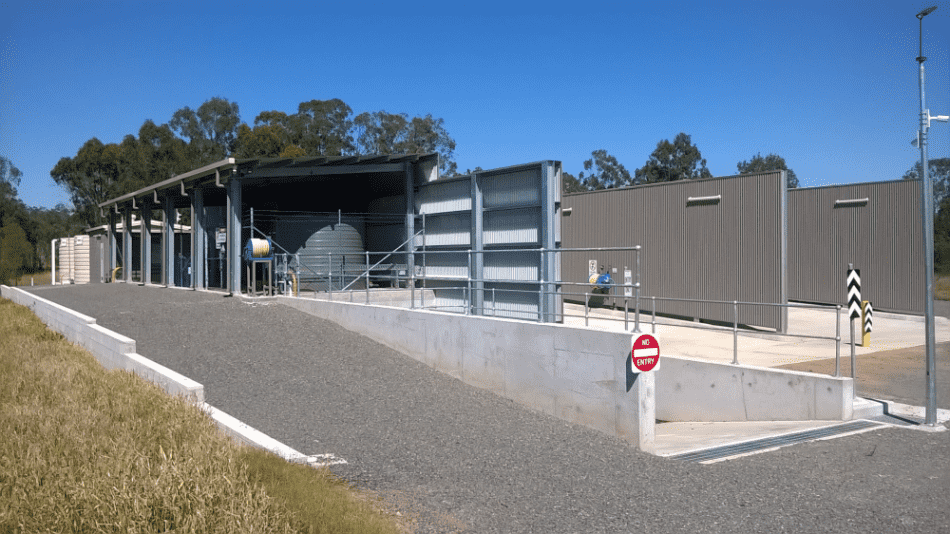

IPS Logistics installed a new un-roofed wash bay in compliance with the Department of Agriculture, Fisheries and Forestry’s (DAFF) guidelines, at its Port of Brisbane facility. The key objectives of the wash bay recycling system were to meet regulatory requirements and minimise the use of potable town water for wash down operations.

Brisbane, Queensland

To help reduce the spread of weeds, a regional council in northern Queensland has built a wash down facility to help people remove weed seeds, soil and other foreign matter from their vehicles and machines. As potable water supply in the region is already under stress a key driver for this project was to recycle the wastewater created by the wash bay, so the council’s consultant engaged MAK Water to design and construct a suitable wash bay water recycling plant.

Aldoga, Queensland

Groundwater Treatment for Motorway Tunnel

The first major road tunnel in Brisbane, The Clem Jones Tunnel (Clem7) is a 6.8 km toll tunnel that connects Brisbane’s inner north to the southern and eastern suburbs, bypassing the Brisbane CBD. Clem7 required a water treatment system to treat the groundwater from the tunnel, eliminating the need to discharge large volumes of water to the sewer or risk pollution of local waterways.

Brisbane, Queensland

SuperCharge Batteries generates wastewater from the battery manufacturing process line. The wastewater needed to be treated to meet trade waste discharge requirements. This included heavy metal removal, pH adjustment and data logging of discharged effluent quality and volume.

Pemulwuy, New South Wales

Solutions for Marine Contractor

MAK Water designed and installed a Gravity Clarifier System to a 2,000m2 marina wash bay in Victoria. The plant was commissioned and operational for several months, then developed complications to the discharge pit pumps, that send captured wash water into the MAK Water plant. Stones had begun to accumulate in the pit, consequently causing damage to the submergible pumps which required rebuilding.

Martha Cove, Victoria

Water Clarification

Related Solutions

Dissolved Air Flotation

The MAK Water Dissolved Air Flotation (DAF) system is a superior counter current system designed to achieve maximum treatment efficiency in a compact footprint.

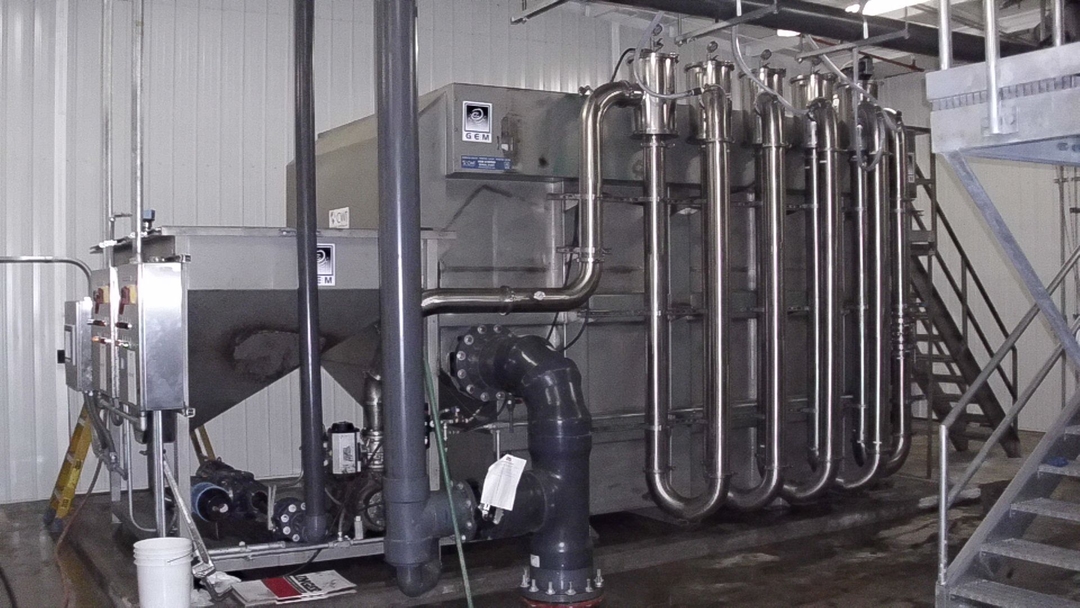

Gas Energy Mixing System

The Gas Energy Mixing (GEM®) System is an innovative and patented approach to wastewater treatment. The GEM System removes higher levels of contaminants than conventional dissolved air flotation (DAF) systems, using less chemicals, while generating significantly drier sludge.

Lamella Clarifier

Lamella clarifiers can manage feed water with high concentration of suspended solids.

Oil Water Separators

MAK Water’s Clearmake™ oil and water separators remove free-floating hydrocarbons such as diesel, hydraulic fluid oil and heavy suspended solids from wastewater.

Pump Station

The Clearmake™ Pump Station is designed to transfer water to a local sewer connection or to a downstream treatment process cost-effectively when gravity cannot assist