Belt Filter

The Belt Filter (BF) is a gravity filtration system that provides effective mechanical filtration of solids from wastewater in a range of applications. The Belt Filter assembly features a belt chassis housed in a polypropylene tank, mounted on a stainless-steel support frame .The filter mesh is available in sizes from 40 µm to 5,000 µm and is woven from high-quality polyester fibres in various patterns to optimise filtering efficiency and flow capacity. Adding a coagulant upstream can enhance solids removal by capturing finer particles.

Standard models come with a static scraper that removes solids from the belt and a spray bar that washes out particles lodged in the belt mesh. For high-solids applications, an optional mechanical rotary scraper and additional washing spray bar are available. This design makes the Belt Filter ideal for municipal effluent polishing, sludge thickening, and primary filtration for food processing wastewater—including dairies, abattoirs, breweries, fruit and vegetable processing, as well as aquaculture filtration and waste recycling water treatment.

Key advantages

- Low Capital and Operating Costs: Cost-effective to purchase and operate.

- Long Service Life: Designed for durability over extended periods.

- Compact, Modular Design: Ideal for limited spaces and scalable for future expansion.

- Easy Installation: Simple setup process.

- Retrofit Capability: Can be integrated into existing process trains seamlessly.

Technical Specifications

Standard Specifications

Parameter | Units | Belt Filter Model | ||||

|---|---|---|---|---|---|---|

2.1C | 2.1D | 3.6D | 3.6M | |||

| Max capacity for mechanical filtration A | m3/h | 6 - 100 | 10 - 170 | 20 - 400 | 60 - 800 | |

| Max capacity for chemical / mechanical filtration A | 1 - 2 | 2 - 4 | 3 - 6 | 6 - 12 | ||

| Available belt filter mesh openings | µm | 40 - 5,000 | 60 - 5,000 | |||

| Belt chassis length | mm | 2,100 | 3,600 | |||

| Belt chassis width | 300 | 500 | 1,000 | |||

| Belt filter assembly length (approx.) | L | 2,567 | 2,773 | 4,263 | 4,764 | |

| Belt filter assembly width (approx.) | W | 530 | 776 | 1,276 | ||

| Belt filter assembly height (approx) | H | 1,305 | 1,525 | 1,688 | ||

| Solid Discharge Height (approx) | SH | 926 | 936 | 1,419 | 1,258 | |

| Inlet Height (approx) | IH | 1,149 | 1,152 | 1,587 | 1,441 | |

| Washing water Drain Height (approx) | DH | 624 | 623 | 1,123 | 956 | |

| Belt drive motor | kW | 0.18 | 0.25 | |||

| Mechanical rotary scraper drive motor (option) | 0.12 | |||||

| Belt speed range | m/s | 0.2 - 0.7 | ||||

| Tank inlet connection, flanged | mm | DN80 | DN125 | DN150 | ||

| Tank outlet conneciton, flanged | 2x DN80 | 2x DN100 | 2x DN125 | 2x DN150 | ||

| Washwater discharge connection, flanged | DN80 | |||||

| Washwater supply connection | DN15 | |||||

| Minimum washwater requirement (min 4 bar) | L/min | 30 | ||||

| Empty weight Belt Filter assembly (approx.) | kg | 100 | 120 | 200 | 310 | |

A. Maximum allowable wastewater/sludge feed temperature is 50oC

Standard Inclusions and Options

Equipment | Belt Filter Model | ||

|---|---|---|---|

Standard | Option | ||

| Belt Filter assembly including belt chassis installed in polypropylene tank mounted on a stainless steel support frame. Belt manufactured in woven high quality polyester fibres. Standard system includes belt drive motor, single washing spray bar with solenoid, and pressure transducer in tank for continuous level measurement. | ✓ | - | |

| Belt Filter internal steel components, assembly support frame, washing spray bar(s) and optional mechanical rotary scraper and optional additional washing spray bar. | 304SS | ✓ | - |

| 316SS | - | o | |

| Mechanical rotary scraper | - | o | |

| Additional washwater spray bar with solenoid | - | o | |

Instrumentation & Controls | Standard | Option |

|---|---|---|

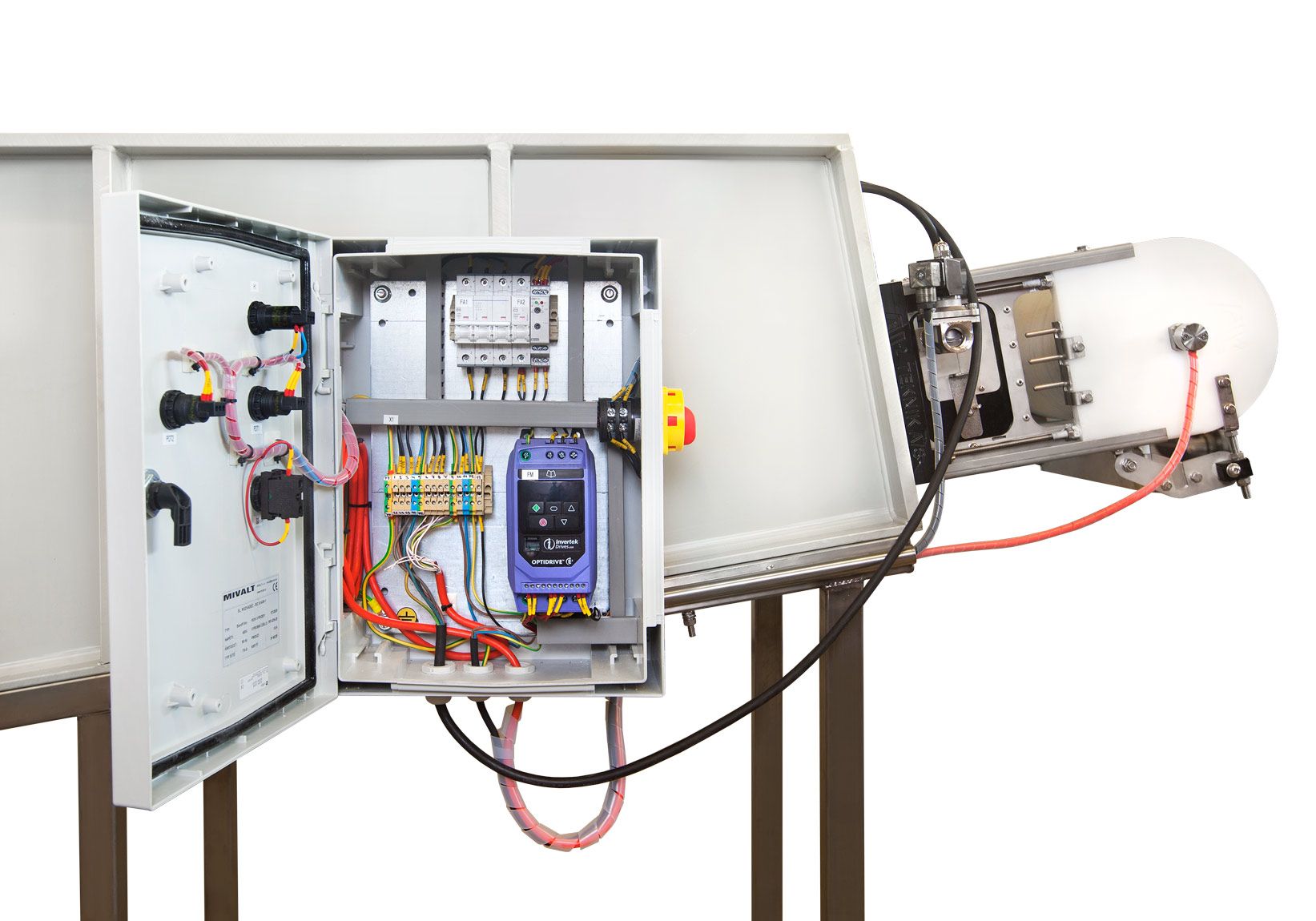

| Control Panel in 316SS enclosure 1 | ✓ | - |

| VFD for drive motor in Control Panel | ✓ | - |

| Level measurement (pressure transducer) for tank inlet, 24VDC | ✓ | - |

| Solenoid valve for washwater, 24VDC (single washing spray bar) | ✓ | - |

| Solenoid valve for washwater, 24VDC (additional washing spray bar) | - | o |

*1 Control Panel mounted on BF, compliant to AS/NZS 3000, includes PLC and touch screen interface, including: VFD for belt drive motor, starters for feed & filtrate pumps (by others), level input for sludge tank and filtrate tank, continuous level measurement in tank via pressure transducer w/ PID control for belt speed, solenoid valve(s) for washwater operation, starter for optional rotary scraper motor for on/off control. Field wiring between Control Panel and equipment/instruments by others.

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Slurry Dewatering for Pet Food Manufacturer

A pet food manufacturing facility in Western Sydney, NSW, needed to separate residual product from washdown water in a variable slurry mixture created from a daily cleaning-in-place (CIP) process. The slurry was not able to be treated in the site’s wastewater treatment plant and therefore required filtration at the outlet source. MAK Water was asked to provide a belt filtration trial unit to provide proof of concept to build to build a business case for capital investment.

Ingleburn, New South Wales

A manufacturer of solid & liquid plant nutrition and soil amendment products in Victoria was looking to improve efficiency. Sludge residues accumulate in the tanks used for product blending through the manufacturing process. This sludge comprises the concentrated raw/precursor solid product and some inert debris. During the cleaning & rinsing of these process tanks, the company has been wasting these sludge residues. However, given this sludge contains the concentrated precursor product, ideally this should be recovered and processed into a valuable liquid fertiliser product. MAK Water was selected to provide a Belt Filter (BF) trial plant for the company to operate and test onsite over a 2-week period. The purpose of the trial was to determine the filtering performance, determine the hydraulic capacity required for the site, and ultimately prove the business case for a full-scale BF. They successfully trialled sludge from various process tanks at various flow rates, and operating the BF at different speeds while adjusting the washing system for different on/off durations.

Victoria

Water Filtration Systems

Related Solutions

Demineralisation Deionisation with ion absorption

MAK Water’s Deionisation (MAKPAK) Plants are designed to treat mains supplied potable water, with a typical conductivity of < 60 μS/cm, to produce high purity deionised water with a conductivity of < 3 μS/cm.

Multimedia Filtration

MAK Water’s Multimedia Filtration (MMF) plants are designed to treat ground water, surface water, tertiary treated effluent, storm water or wastewater with <30 mg/L of total suspended solids.

Cloth Media Filters

The MITA Water Technologies Cloth Media Filters (CMF) deliver effluent quality comparable to sand filters (TSS < 5 mg/L).

Ultrafiltration

MAK Water’s Ultrafiltration (UF) plants are designed to treat ground water, surface water, tertiary treated effluent, storm water or wastewater with turbidity <300 NTU.

Ultrafiltration-basic

Ultrafiltration (UF-B) plants are designed to treat surface water, tertiary treated effluent, storm water and waste water to achieve potable/process water or may be used as pre-treatment to reverse osmosis.

Water Softening with Ion Exchange

MAK’s Water Softening plants (WSP) are designed to reduce hardness from water sources that may have negative downstream implications such as scaling of pipework and equipment.