Multimedia Filtration

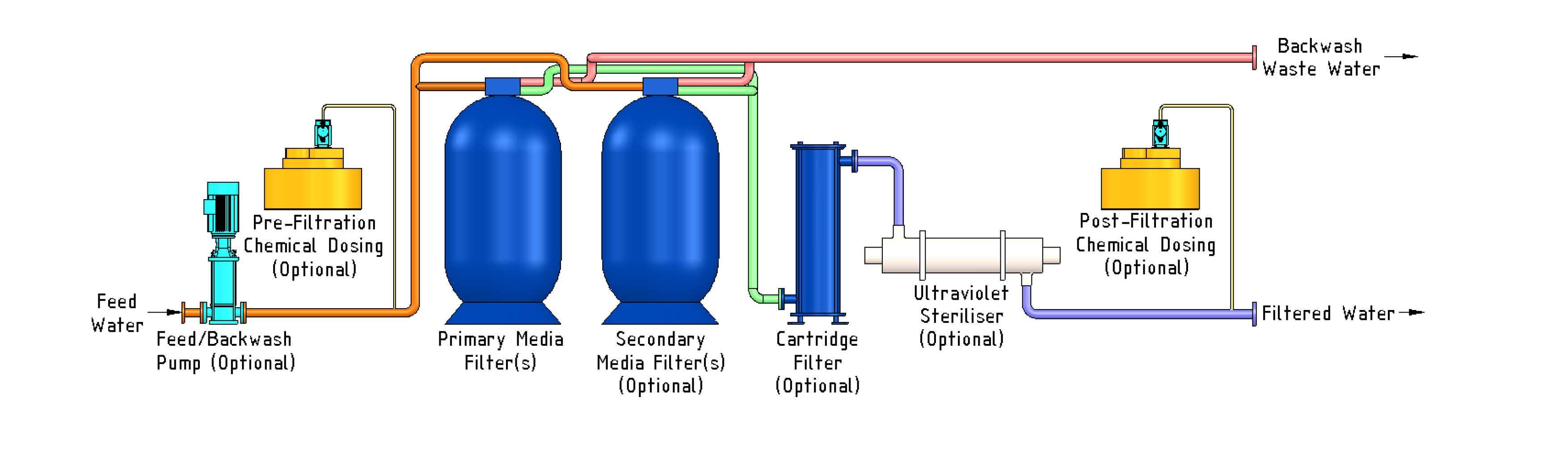

MAK Water’s Multimedia Filtration (MMF) plants are designed to treat ground water, surface water, tertiary treated effluent, storm water or wastewater with <30 mg/L of total suspended solids. Standard filtration media includes sand media for suspended solids removal, granular activated carbon (GAC) for removal of organics, colour, odour or chlorine and DMI-65 greensand for dissolved iron and manganese. Additional filtration media, such as calcite for hardness correction and various ion exchange resins, are available on request.

Extra pre-filtration and post-filtration treatment steps may be added as required to suit feed water conditions and/or treated water quality requirements. The MAK Water MMF plants are available as skid mounted or containerised systems.

Technical Specifications

Standard Specifications

Parameter | Units | MMF-0050 | MMF-0150 | MMF-0250 | MMF-0500 | MMF-1000 | MMF-2500 | MMF-5000 | |

|---|---|---|---|---|---|---|---|---|---|

| Filtrate flow rate*1 | m3/day | 50 | 150 | 250 | 500 | 1,000 | 2,500 | 5,000 | |

| Feed/filtrate water flow | m3/hr | 2.1 | 6.4 | 10.6 | 21.3 | 42.6 | 106.4 | 212.8 | |

| Backwash water flow | m3/hr | 1.5~3 x feed water flow (varies according to configuration and feed water quality) | |||||||

| Power consumption | Feed/backwash pump*2, *3 | kW | 1.1 | 2.2 | 3 | 5.5 | 11 | 30 | 55 |

| Air conditioned containers*2 | 1.9 kW per 20’ container / 3.8 kW per 40’ container (includes internal lighting) | ||||||||

| Power supply | - | AC 415V, 3 Phase 50 Hz (AC 240V, 1 Phase 50 Hz available for small plants) | |||||||

| Recovery rate | % | 90~98% (varies according to media selection and feed water quality) | |||||||

| Filtration velocity | Sand Media | m/hr | 20 (design value can be adjusted to suit feed water quality) | ||||||

| DMI-65 media | 10 (design value can be adjusted to suit feed water quality) | ||||||||

| Empty bed contact time | GAC media | min. | 10 (design value can be adjusted to suit feed water quality) | ||||||

| UV dose rate*2 | mJ/cm2 | Typical >40 @ 90% UVT | |||||||

| Feed/backwash water inletpressure | Without pump | kPa | 300~600 (pressurised feed/backwash water by client) | ||||||

| With pump | ≥20 (flooded suction) | ||||||||

| Pressure drop | Sand media | kPa | 50~200 | ||||||

| DMI-65 media | 50~200 | ||||||||

| GAC media | 50~200 | ||||||||

| Cartridge filter*2 | 50~200 | ||||||||

| Ambienttemperature(min/max) | Skid mounted | °C | 5~30 | ||||||

| Containerised | -5~40 | ||||||||

| Containerised with insulation | -15~50 | ||||||||

Parameter | Units | Sand media | DMI-65 media | GAC media | |||

|---|---|---|---|---|---|---|---|

Feed water | Filtrate | Feed water | Filtrate | Feed water | Filtrate | ||

| Temperature | °C | 5~36 | 5~36 | 5~36 | |||

| Total suspended solids (TSS) | mg/L | <30 | <5*4 | <5 | <5*4 | <5 | <5*4 |

| Turbidity | NTU | <15 | <5*4 | <5 | <5*4 | <5 | <5*4 |

| Filtration degree | µm | 5 | - | - | |||

| Dissolved iron & manganese | mg/L | - | - | <10 | <0.1 | - | - |

| Total organic carbon (TOC) | mg/L | - | - | - | - | <10 | <0.1 |

| Colour | HCU | - | - | - | - | Up to 98% reduction | |

| Trihalomethanes | µg/L | - | - | - | - | <1,000 | <250*5 |

*1Based on operating for 23.5 hours per day with 0.5 hours downtime for backwashing, *2Optional equipment, *3Pump size may vary according to feed water quality and plant configuration, *4Nominal, can be improved with optional 1 micron cartridge filter, *5Dependent on competing organics

Standard Inclusions and Options

Equipment | MMF-0050 | MMF-0150 | MMF-0250 | MMF-0500 | MMF-1000 | MMF-2500 | MMF-5000 | |

|---|---|---|---|---|---|---|---|---|

| Skid mounted plant / equipment | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| uPVC / HDPE inlet and outlet pipe work / manifolds, manual isolation and sampling valves | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Auto-backwashing FRP filter vessel(s) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Feed / backwash pump with electrical controls | o | o | o | o | o | o | o | |

| Chemical dosing system(s)*1 | o | o | o | o | o | o | o | |

| PVC cartridge filter(s) (1µm) | o | o | o | o | o | o | o | |

| UV steriliser | o | o | o | o | o | o | o | |

| Containerised with air conditioning, overhead lighting and GPO’s for maintenance | Standard supply | o | o | o | o | o | o | o |

| With non-slip floor coating | o | o | o | o | o | o | o | |

| With non-slip floor coating and insulation | o | o | o | o | o | o | o | |

| PLC control system with touch screen HMI | o | o | o | o | o | o | o | |

| Instrumentation | Standard package | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Premium package with ClearAccess™ remote monitoring*2 | o | o | o | o | o | o | o | |

Instrumentation and Controls | Sand media instrument package | DMI-65 media instrument package | GAC media instrument package | ||||

|---|---|---|---|---|---|---|---|

Standard | Premium | Standard | Premium | Standard | Premium | ||

| Pressure gauges on inlet/outlet manifolds | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Raw water and filtrate tank float level switches | ✓ | - | ✓ | - | ✓ | - | |

| Raw water and filtrate tank level transmitters | - | ✓ | - | ✓ | - | ✓ | |

| Pressure switch (feed/backwash pump discharge) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Chemical dosing tank float level switches | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Pressure transmitters on inlet/outlet manifolds | - | ✓ | - | ✓ | - | ✓ | |

| Flow transmitter (treated water) | - | ✓ | - | ✓ | - | ✓ | |

| Turbidity analyser (treated water) | - | ✓ | - | ✓ | - | - | |

| ClearAccess™ remote monitoring and control capabilities | - | ✓ | - | ✓ | - | ✓ | |

| pH transmitter (with optional acid or caustic dosing) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| ORP transmitter (with optional de-chlorination/SMBS dosing) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| ORP transmitter (with DMI-65 media and hypo dosing) | - | - | ✓ | ✓ | - | - | |

| UV intensity sensor/monitor (with optional UV steriliser) | - | ✓ | - | ✓ | - | ✓ | |

*1DMI-65 media requires flow paced hypochlorite dosing system for iron and manganese removal, *2Requires PLC control system

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

As part of the expansion of the Patrick Terminals, Port of Brisbane operations, a new water efficient wash bay was required. It was important the solution complied with the Department of Agriculture, Fisheries and Forestry’s standards and maximised the reuse of the wash water, eliminating any discharge of polluted water to local water ways.

Brisbane, Queensland

MAK Water was engaged to deliver the process water and potable water treatment plants for the Cobre Project, one of the larger copper mine developments in Central America. As this was a Greenfield project and the exact feed water quality was uncertain, MAK Water proposed a robust process incorporating: • Chemical flocculation to improve efficiency of solids separation • Lamella clarification as pre-treatment to account for spikes in suspended solids, and • Media filtration in order to achieve the final quality of process and potable water for the site. MAK Water was selected thanks to its innovative modular containerised design, extensive experience in delivering high quality packaged water treatment plants for remote mining projects, and its ability to customise the solution to meet the project requirements.

Donoso, Colon Province, Panama

Potable Water for Meat Processing Facility

A leading Western Australian meat processor and exporter required additional treatment of the dam water it was using in its factory as wash down water to improve the standard of its abattoir and maintain international accreditation. MAK Water worked closely with the client to review water data, site requirements, and provide a number of possible equipment solutions. The customer selected a custom filtration and sterilisation plant, specifically designed by MAK Water to meet its requirements and provide a reliable long-term solution with the appropriate degree of filtration and UV log reduction.

Southwest region, Western Australia

Potable Water Treatment for Primary School Campus

When the Swan Christian College Association was planning to build a new secondary campus in the Perth Hills they identified that the new development would be without access to water and wastewater services for several years. They required an alternative medium-term source of potable water and engaged a local hydraulic consultant to manage the process. MAK Water was engaged to design and manufacture a system to treat the available bore water for potable use at the school and maintain compliance with the Australian Drinking Water Guidelines (ADWG). MAK Water also consulted with local authorities on behalf of the school to develop and gain approval for the required Drinking Water Quality Management Plan

Parkerville, Western Australia

What people are saying

Kim demonstrated a highly organised and proactive approach, ensuring that the project progressed smoothly from planning through to completion. Kim and the rest of the MAK Water team were also exceptionally easy to work with.

Jacob Giovenco - Senior Project Engineer

Degnan

Degnan are very satisfied with the service offered by the MAK Water Team. From the initial concept design through to installation and commissioning the team at MAK Water were efficient and easy to work with.

Andrew Bridson - Design Manager

Degnan

Water Filtration Systems

Related Solutions

Belt Filter

The Belt Filter provides effective mechanical filtration for removing solids from wastewater in a range of applications.

Demineralisation Deionisation with ion absorption

MAK Water’s Deionisation (MAKPAK) Plants are designed to treat mains supplied potable water, with a typical conductivity of < 60 μS/cm, to produce high purity deionised water with a conductivity of < 3 μS/cm.

Cloth Media Filters

The MITA Water Technologies Cloth Media Filters (CMF) deliver effluent quality comparable to sand filters (TSS < 5 mg/L).

Ultrafiltration

MAK Water’s Ultrafiltration (UF) plants are designed to treat ground water, surface water, tertiary treated effluent, storm water or wastewater with turbidity <300 NTU.

Ultrafiltration-basic

Ultrafiltration (UF-B) plants are designed to treat surface water, tertiary treated effluent, storm water and waste water to achieve potable/process water or may be used as pre-treatment to reverse osmosis.

Water Softening with Ion Exchange

MAK’s Water Softening plants (WSP) are designed to reduce hardness from water sources that may have negative downstream implications such as scaling of pipework and equipment.