Ultrafiltration-basic

Ultrafiltration (UF-B) plants are designed to treat surface water, tertiary treated effluent, storm water and waste water to achieve potable/process water or may be used as pre-treatment to reverse osmosis. They treat a wide range of highly variable waters with <50 NTU of turbidity and <100 mg/L of suspended solids.

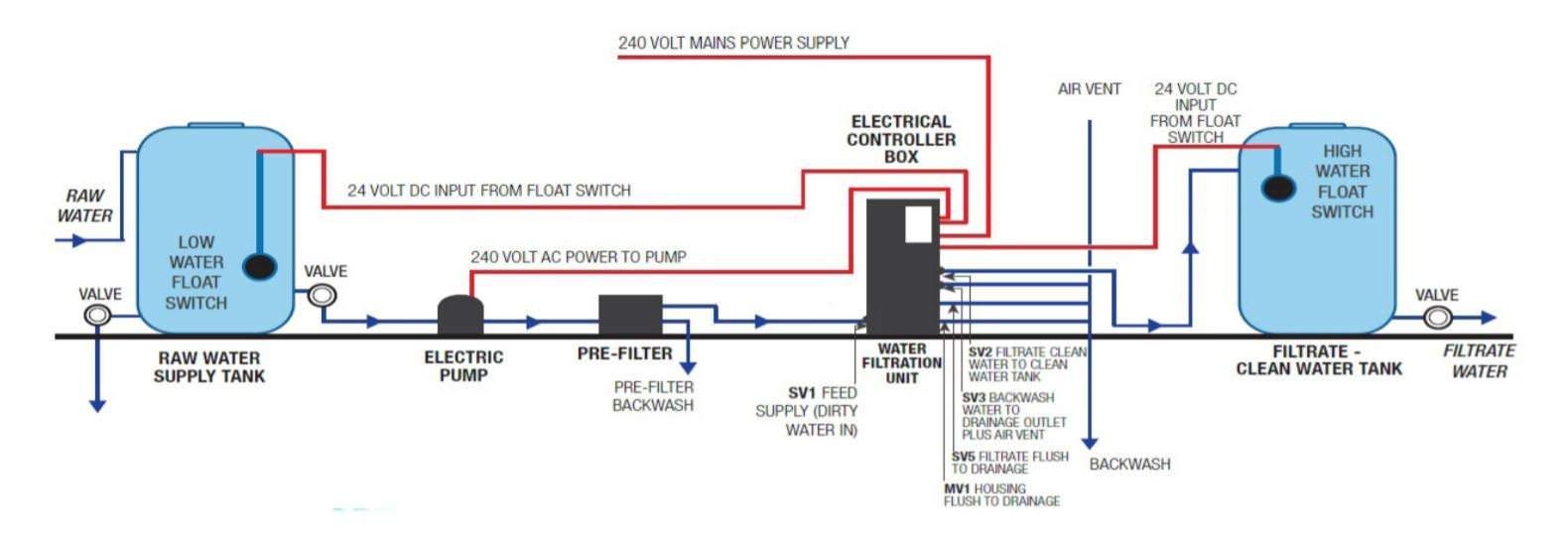

The standard treatment process includes optional pre-filtration (500 micron screen filter), Ultrafiltration process and automatic backwashing for membrane cleaning. Additional pre or post UF treatment steps may be added to suit feed or filtered water requirements such as iron removal, pH correction or sterilisation. The MAK UF plants are available as skid mounted units or containerised systems.

Technical Specifications

Standard Specifications

Parameter | Units | UF-B-20 | UF-B-40 | UF-B-60 | UF-B-80 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Filtrate Flow Rate(varies according to feed water quality) | m3/day | 20 | 40 | 60 | 80 | |||||||||||

| Filtrate Recovery Rate | % | 90 – 98% (varies according to feed water quality) | ||||||||||||||

| Membrane Type | - | Outside in, dead end | ||||||||||||||

| Filtrate Turbidity | NTU | <0.1 (typical) | ||||||||||||||

| Raw Water Turbidity (max) | NTU | <50 | ||||||||||||||

| Raw Water TSS (max) | mg/L | <100 | ||||||||||||||

| Feed pH range | pH | 6 – 9 (exposure to chlorine or chloramines is not recommended in feeds below pH 6.5) | ||||||||||||||

| Allowable pH range for chemical cleaning (by others) | pH | 2 - 10 | ||||||||||||||

| Raw Water Temperature | °C | 15 ~ 35 | ||||||||||||||

| Ambient Design Temperature | °C | 5 ~ 45 (-15 ~ 50 for insulated containerized system) | ||||||||||||||

| Feed-Pre Screen Requirements | micron | 500 or finer (unscreened or coarsely screened raw water may reduce membraneoperating life) | ||||||||||||||

| Feed Water Inlet Pressure (min) | kPa | 100 kPa | ||||||||||||||

| Feed Water Inlet Pressure (Max) | kPa | 200 kPa (recommend <150) | ||||||||||||||

| Filtrate Discharge Pressure Drop | kPa | ~30 | ||||||||||||||

| Backwash Discharge Pressure Drop | kPa | ~20 | ||||||||||||||

| Power Supply | - | AC 110/240 V, 1 Phase, 50/60 Hz | ||||||||||||||

| Power Consumption | kW | 0.5 | 0.5 | 0.5 | 0.5 | |||||||||||

| No. Containers (Optional) | - | 1 x 10’ | 1 x 10’ | 1 x 10’ | 1 x 10’ | |||||||||||

Standard Inclusions and Options

Equipment | UF-B-20 | UF-B-40 | UF-B-60 | UF-B-80 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Skid Mounted Plant & Equipment | ✓ | ✓ | ✓ | ✓ | ||||||||||||

| Flow Control Vale | ✓ | ✓ | ✓ | ✓ | ||||||||||||

| UF Feed Pump | o | o | o | o | ||||||||||||

| Pre-filtration – Manual 500 Micron Screen | o | o | o | o | ||||||||||||

| Automatic Membrane Backwash System | ✓ | ✓ | ✓ | ✓ | ||||||||||||

| Control System with LCD graphic display | ✓ | ✓ | ✓ | ✓ | ||||||||||||

| Containerized system, c/w A/C & Lights | o | o | o | o | ||||||||||||

| Container Insulation (walls & ceiling) | o | o | o | o | ||||||||||||

| Container non-slip floor coverings | o | o | o | o | ||||||||||||

| Additional UV Sterlisation | o | o | o | o | ||||||||||||

| Filtrate Distribution Pump Set | o | o | o | o | ||||||||||||

Instrumentation | Standard Package | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure Gauges | ✓ | |||||||||||||||

| Pressure Transmitters | o | |||||||||||||||

| Flow Sensor | o | |||||||||||||||

| Turbidity Transmitter | o | |||||||||||||||

| Float Switches (Feed/Filtrate, Tanks) | o | |||||||||||||||

Disclaimer: We continuously update and improve our products and services, contact us for more detailed information or to confirm specifications. MAK Water takes no responsibility for any errors resulting from the use of information contained on this website.

Applications

Real-world examples

Potable Water for Bottling Facility

A bottled water manufacturer in New Zealand needed to be sure that their artesian bore water would be delivered to their customers consistently at the right quality. The company engaged MAK Water to deliver two Ultrafiltration (UF-B) plants. The membrane filtration process acts a physical barrier to viruses and pathogens, and removes any suspended solids that may be present in the water. This process was selected over conventional sand filtration or reverse osmosis as it purified the water without altering the chemical composition and enabled the bottled water to remain a consistent quality despite some variation in the raw water supply conditions.

South Island, New Zealand

Oyster Farm Wash Water Recycling

One of the largest producers of Oysters on the south coast of NSW was using a large volume of potable water for the washing and shucking of their Oysters. This water made just a single pass over the Oysters before it made its way to sewer. To reduce water consumption and minimise impact on the environment, the customer decided they wanted to recycle this water back to the front of their process. To achieve this, they needed a system that could remove sediment from the wastewater and provide protection from bacterial build up.

New South Wales

Water Filtration Systems

Related Solutions

Belt Filter

The Belt Filter provides effective mechanical filtration for removing solids from wastewater in a range of applications.

Demineralisation Deionisation with ion absorption

MAK Water’s Deionisation (MAKPAK) Plants are designed to treat mains supplied potable water, with a typical conductivity of < 60 μS/cm, to produce high purity deionised water with a conductivity of < 3 μS/cm.

Multimedia Filtration

MAK Water’s Multimedia Filtration (MMF) plants are designed to treat ground water, surface water, tertiary treated effluent, storm water or wastewater with <30 mg/L of total suspended solids.

Cloth Media Filters

The MITA Water Technologies Cloth Media Filters (CMF) deliver effluent quality comparable to sand filters (TSS < 5 mg/L).

Ultrafiltration

MAK Water’s Ultrafiltration (UF) plants are designed to treat ground water, surface water, tertiary treated effluent, storm water or wastewater with turbidity <300 NTU.

Water Softening with Ion Exchange

MAK’s Water Softening plants (WSP) are designed to reduce hardness from water sources that may have negative downstream implications such as scaling of pipework and equipment.